Two more to go!

At the south end of the vast manufacturing facility, a 16-tonne spool is lifted out of its transport frame and inserted into the bespoke tool that will unwind the 900 metres of jacketed conductor it contains. The operation is the first act of the coil fabrication process and it has been repeated 56 times already since the first "dummies" were produced back in 2016.

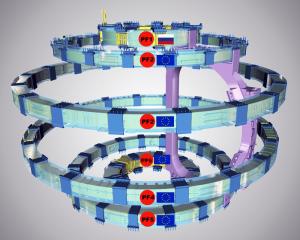

Procured by China and manufactured by the Institute of Plasma Physics of the Chinese Academy of Science (ASIPP), the conductor is destined for poloidal field coil #3 (PF3). In order to form the "double pancakes" that each coil is built from, conductor lengths are fed from two spools simultaneously ("two-in-hand" winding) to be unwound, straightened, cleaned, curved to the correct degree and wrapped in insulating fibre tape. PF3, which will be assembled from a stack of 8 double pancakes, requires approximately 14 kilometres of cable.

Further down the assembly line, eight double pancakes for poloidal field coil #4 (PF4) have already been stacked. The teams are preparing the coil for ground insulation, an operation which consists in wrapping the stack with nine successive layers of glass-Kapton tape that insulate it electrically.

The delicate wrapping operations are done by hand, as the helium inlets situated at regular intervals do not allow the automation of the process. Following ground insulation, the coil pack will undergo impregnation, further assembly (clamps, protection covers, pipes...) and finally cold testing.

¹ Europe is responsible for poloidal field coils #2, #3, #4, #5 and #6. (PF1 is procured by Russia.) Due to schedule constraints and space availability, PF6 was manufactured in China under a European contract.