A “record performance” brings assembly back on track

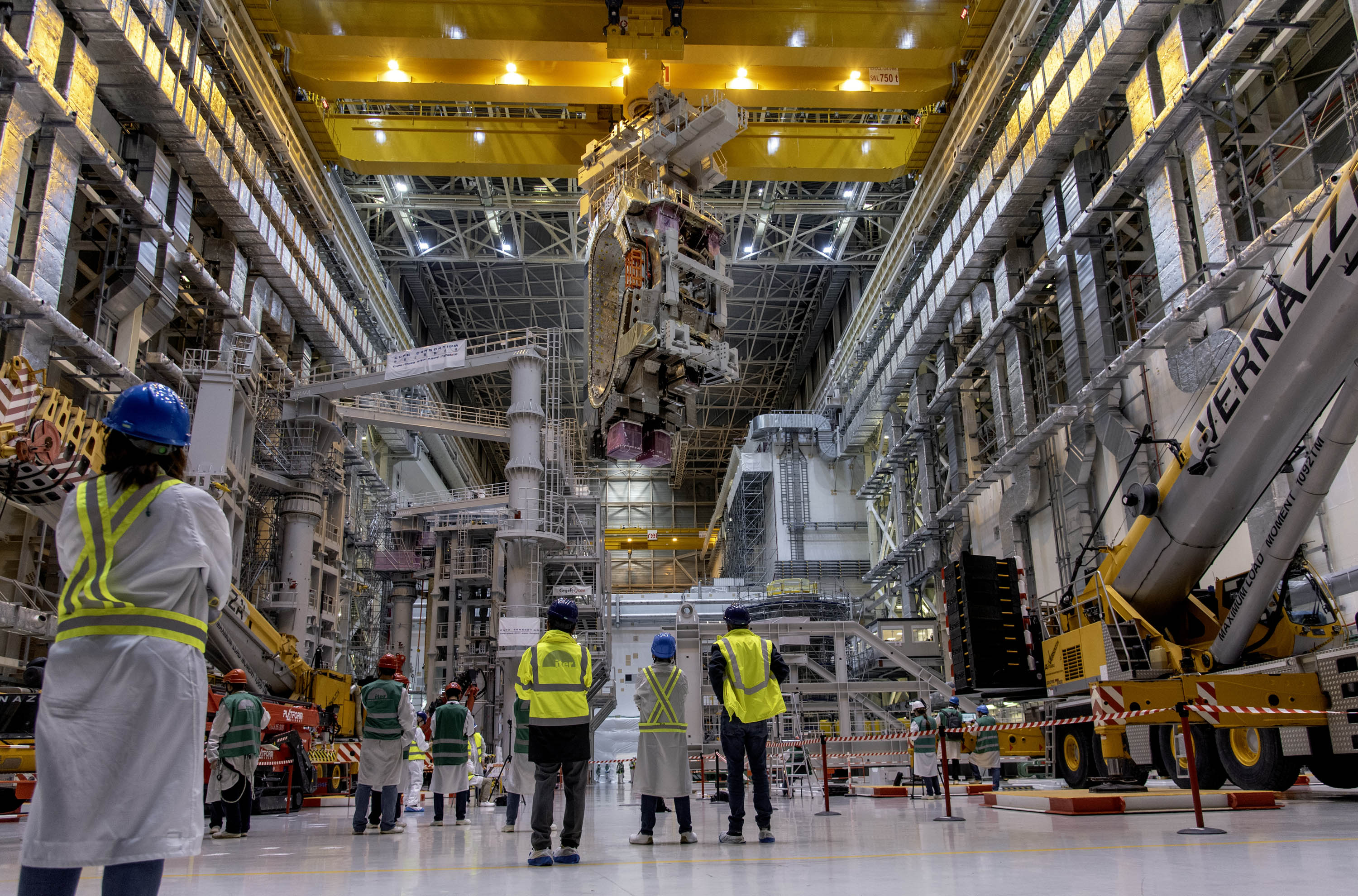

The transfer of sector module #7 to the tokamak assembly pit, on Thursday 10 April, was many things in one. Hailed as a “record performance” by ITER Director-General Pietro Barabaschi, considered a “top-level achievement” by the head of the Construction Project Sergio Orlandi, the operation concentrated most of the challenges ITER must face and overcome during the machine assembly phase.

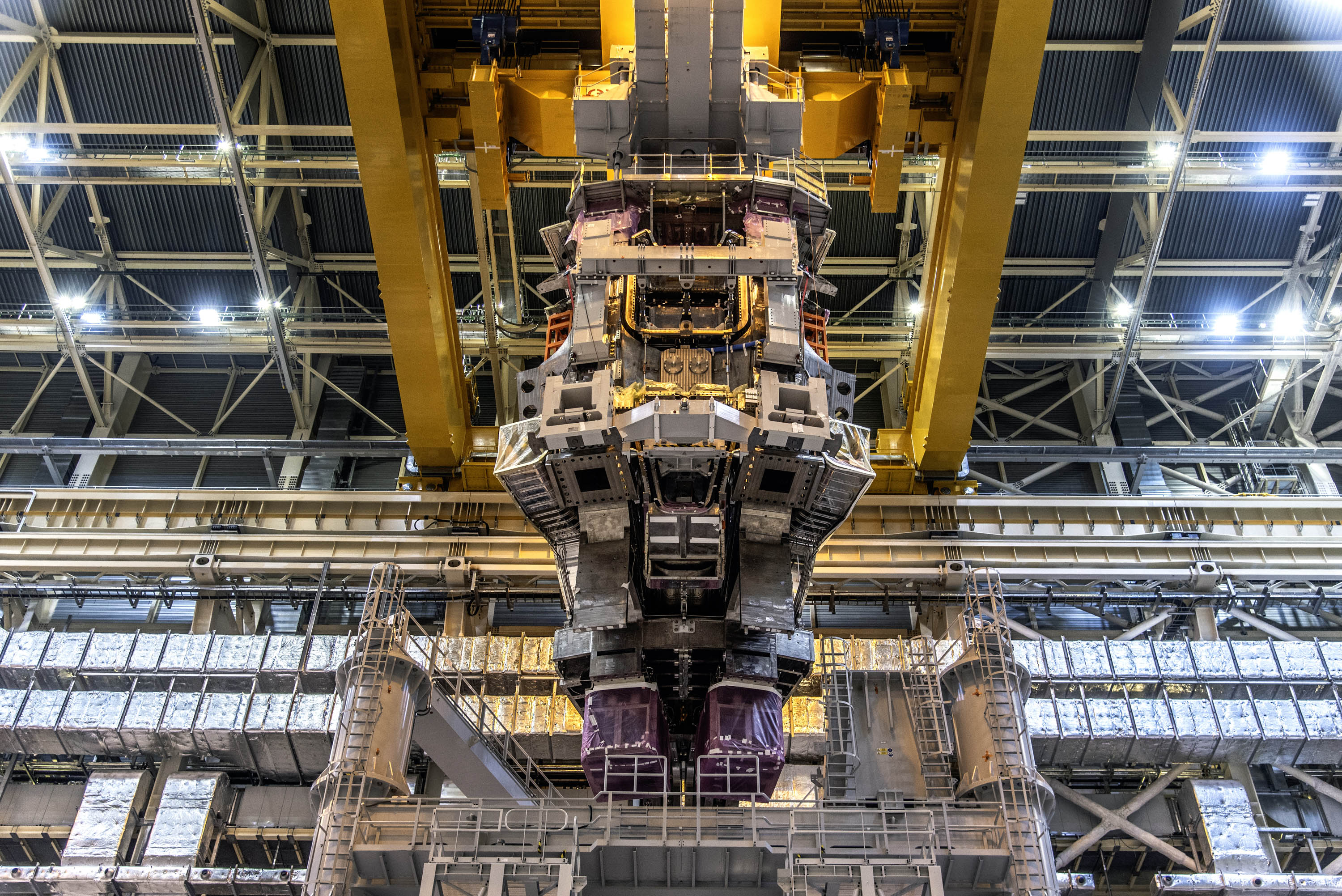

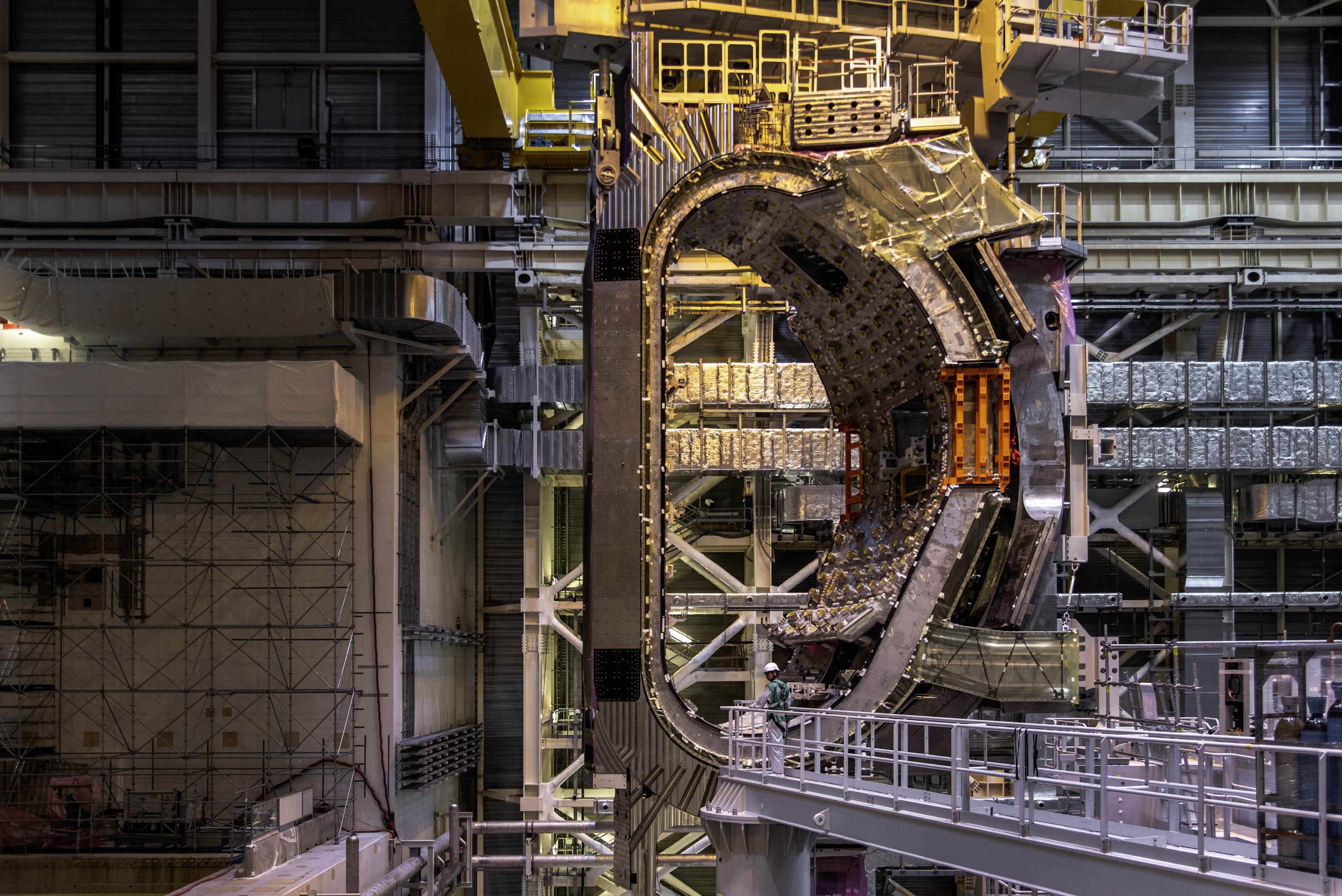

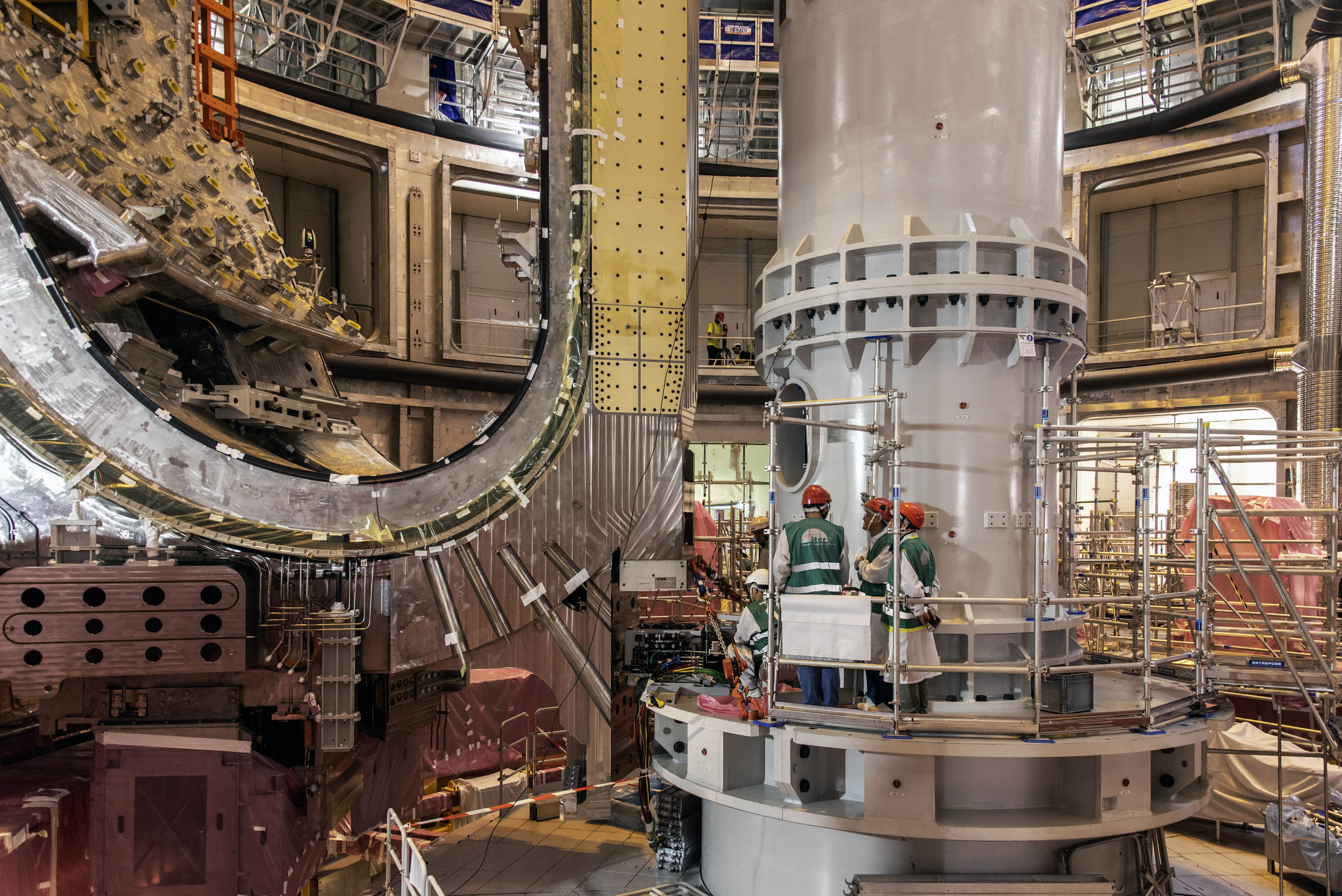

The module itself, one of the nine “building blocks” that will, once assembled and welded, form the tokamak’s doughnut-shaped vacuum vessel, is a unique technological object. As tall as a five-storey building and as heavy as four fully loaded jumbo jets, it is a complex assembly of first-of-a-kind components procured by three different ITER Members: Korea for the vacuum vessel sector at the module’s core as well as the thermal panels that contribute to its insulation, and Europe and Japan for the pair of toroidal field coils that complete the assembly.

Creating a module from these three major components—not to mention all the necessary piping, joining elements and accessories—is a lengthy operation. In 2021 and 2022, the assembly of sector module #6 had required 18 months of work. (Installed in the tokamak pit in May 2022, the module was extracted 14 months later for repair.) The many lessons learned throughout this initial operation were not lost on the teams who were able to divide by three the assembly time of sector module #7 and reduce it to a mere six months and ten days. This accomplishment was celebrated on Friday 28 March, with the teams pledging to do “even better for the next one.”

The experience gained from the initial lifting, transfer and installation of a sector module also proved precious last week. “The cornerstone of the entire operation is the engineering definition of the task, properly documented and well understood by the executants,” explains Daniel Coelho, the ITER assembly engineer who coordinated the operation three years ago and again last week. “Whereas most of the people involved are tasked to apply rules and procedures, we still need a handful of people with a deep understanding of the reasoning behind the rules, in order to properly evaluate deviations to the process that arise and adapt with confidence in case of need.” To reinforce this approach, “veterans” from the sector module #6 operations in May 2022 and July 2023, still present on the ITER site but working in other parts of the project, were temporarily re-allocated to last week’s operation.

As for an airliner, the “take-off” and landing of a sector module are the most delicate phases of the journey. Wednesday, on the eve of the transfer, the teams rehearsed the very first sequence of the operation. Called a “pre-lift,” it consisted of lifting the 1,350-tonne load approximately 50 centimetres—a prelude to its full extraction from the sector sub-assembly tool (SSAT). The pre-lift allows for the thorough testing of every instrument to be involved in the full transfer, the practice of the initial sequences, and the coordination of the personnel involved.

On Thursday morning, three weeks ahead of schedule, the transfer could commence. For those who had been present during the May 2022 operation, everything seemed to go exceptionally quickly and smoothly. And it was not just an impression: although the load travelled at times at the “micro speed” of a few centimetres per second, it seemed to reach the edge of the tokamak pit in record time. “The overhead cranes have proven to be much more reliable, with nearly no delay when compared to the two hours of immobilization we had experienced due to technical issues in 2022,” says Coelho.

By early afternoon, the module had started its descent into the 30-metre-deep tokamak pit. Invisible to the eye, but quite apparent in time-lapse videos, the swinging of the load due to the inevitable “pendulum effect” made the last phase of the insertion particularly delicate (see the pendulum effect in the time-lapse video in this issue). At certain critical points, the clearance between the module and elements inside the tokamak pit did not exceed a few centimetres. “Not a walk in the park…” muses Coelho.

At 10:00 p.m., with the module having reached the bottom of the pit and passed the last major technical hurdle, the teams were confident they could complete the job within hours. A special authorization from ITER management allowed their shift to be extended and by 1:30 a.m., the day’s objective was met—the module had safely landed in its temporary position.

With sector module #6 now being reassembled and scheduled to be returned to the tokamak pit in July, “the present operation brings us back on track for the machine assembly phase” says ITER Machine Assembly Program Manager Jens Reich.

See further information in the photo gallery below.