The A to Z on assembling ITER's largest components

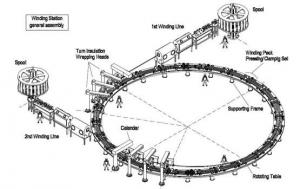

Adjacent to the unloading area a climate-controlled "clean" enclosure is the theatre for winding operations. Lengths of NbTi conductor fed from two spools simultaneously ("two-in-hand" winding) are insulated and wound into a flat, spiralled coil called a double pancake.

"Starting from the conductor spools, two-in-hand double pancakes are wound, and insulated with glass-fibre tape", Byung Su Lim, Poloidal Field Coil Section Leader at ITER, explains. "The winding speed must be synchronized with the speed of insulation wrapping and the tension of insulation tape controlled. The shaping of each termination (for connection one to the other) is performed after the completion of winding."

The total conductor lengths required for the winding stage of manufacture varies from 6 km for PF2 to 14 km for PF3. "The size of each double pancake depends on the dimensions of the final coil," stresses Lim. "Depending on the number of turns in each double pancake and the number of pancakes stacked to form the final coil, each poloidal field coil is unique." Thirty-nine double pancakes will leave the winding facility's assembly line over a six-year period.

"The challenge during this phase is to distribute the resin in a uniform manner," explains Lim. "Pressure is our main ally: propelled by pressure from the lowest point of the double pancake, the resin reaches all areas before flowing out at the highest point. We'll leave plenty of time for the resin to wet the insulation completely and to avoid creating trapped bubbles in the winding."

Once impregnated, the double pancake is put first at atmospheric pressure and then at overpressure, and "cured" for more than 24 hours above 100 degrees Celsius.

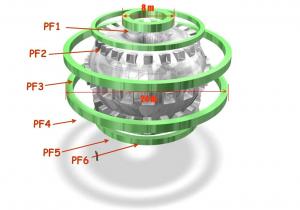

The floor in this area of the winding facility has been reinforced for the exceptional weight of the final assemblies. "Eight double pancakes are stacked to form the winding packs for PF coils 1,3,4 and 5, an respectively six and nine double pancakes for the winding packs of PF 2 and PF6. That puts the completed coils—winding pack plus additional components—at between 200 tonnes and 400 tonnes," says Lim. "These massive components will exit the winding facility on self-propelled transporters."

The size and weight of the poloidal field coils are a particular challenge for manufacturing operations, according to Lim. "Manufacturing tolerance targets have been defined at 3-4 mm—a particularly challenging target for components that measure up to 24 metres in diameter."