Inserting the ship into the bottle

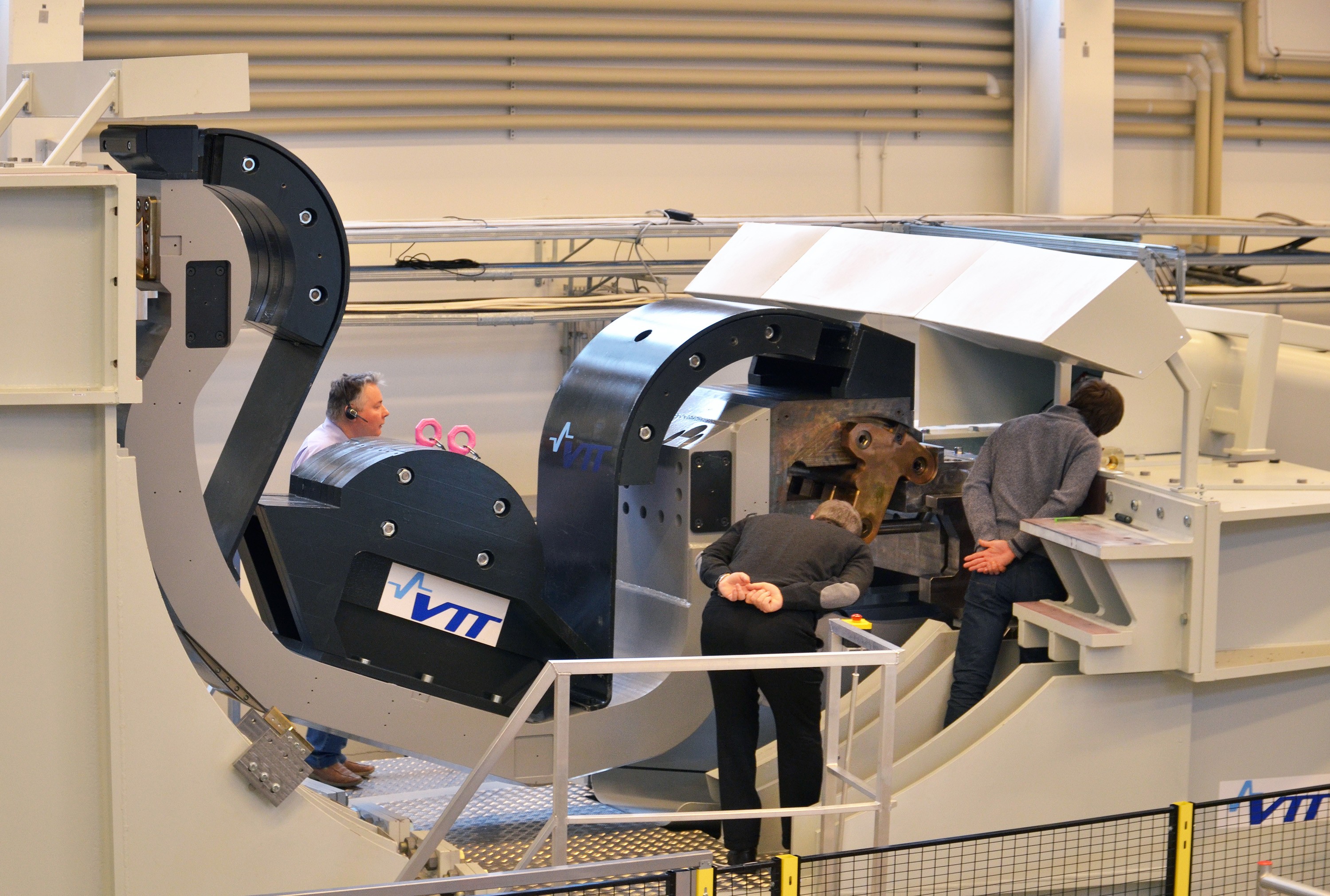

Installing a divertor cassette in the ITER vacuum vessel will be like inserting a model ship into a bottle. Both operations require careful planning, dexterity and millimetric precision within severe space constraints. But where a model ship is meant to remain in the bottle forever, the 54 divertor cassettes need to be replaced at least once during ITER's lifetime.

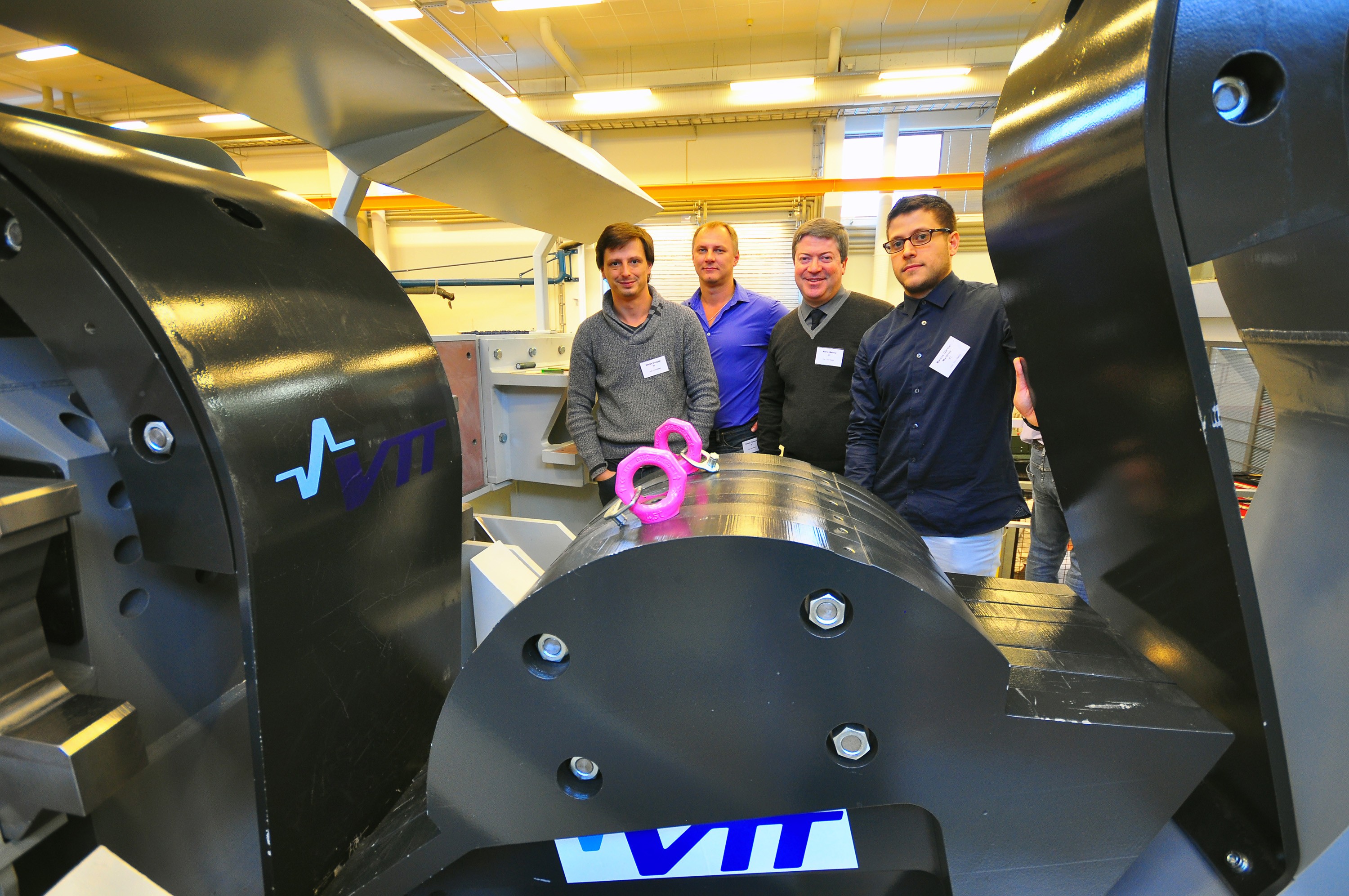

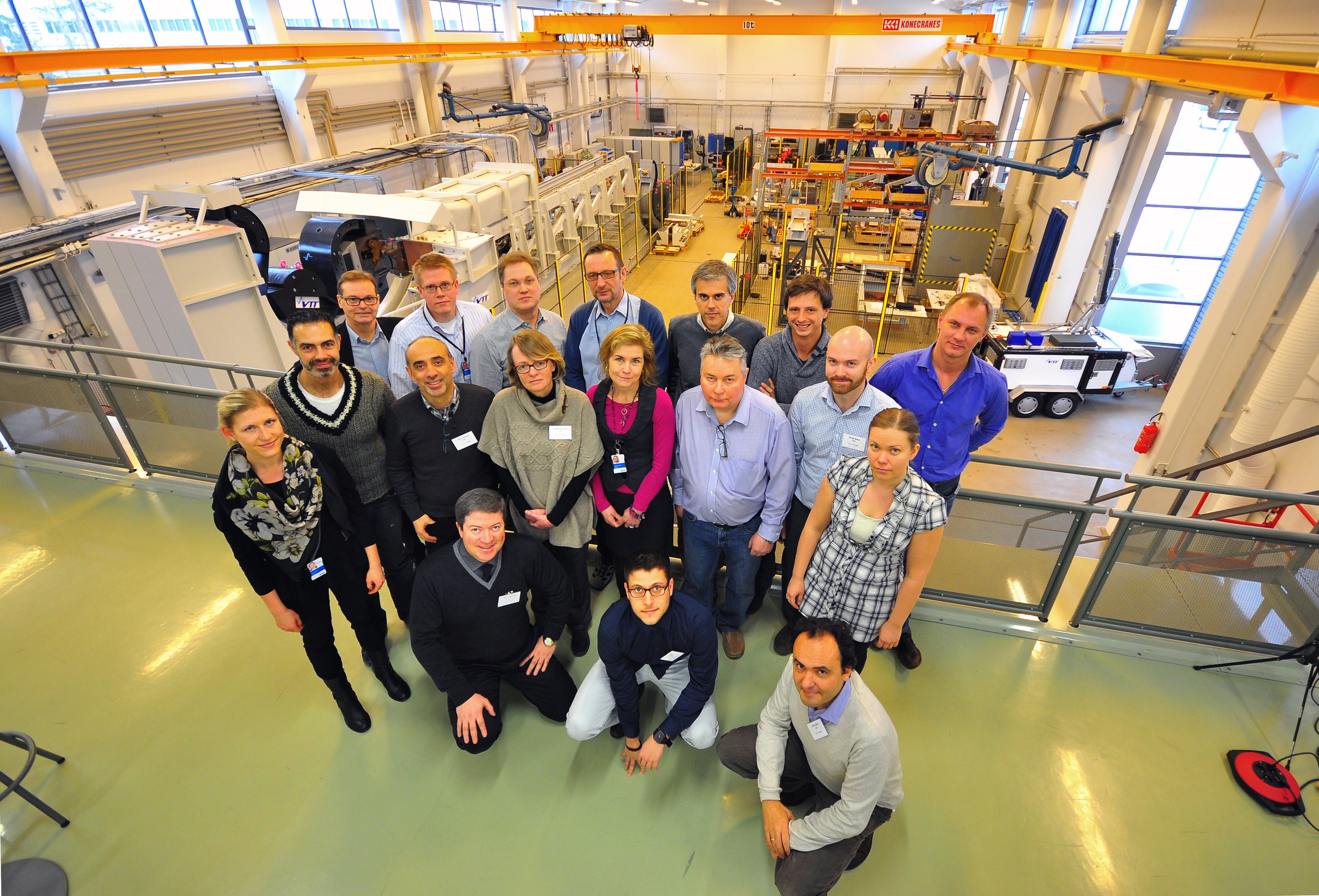

The first Divertor Test Platform was established in the ENEA centre of Brasimone, Italy, under the auspices of the European Fusion Development Agreement (EFDA). As ITER was downsized to its present parameters (and divertor cassette weight had dropped to about 10 tonnes), the challenge was passed on to a team of international experts and a second Divertor Test Platform (DTP2) was established at the VTT Technical Research Centre in Tampere, Finland, some 180 kilometres northwest of Helsinki.

The event also carried a strong significance for the representatives of the European Domestic Agency for ITER, also present in the DTP2 hall. After years of European-financed R&D on the ITER remote handling systems (design, mockup fabrication and demonstrations), the time had come to pass the challenge on to industry — in June 2014, Europe signed a EUR 40 million contract with a partnership of laboratories and companies led by Assystem(2) for the design, manufacturing, delivery, on-site integration, commissioning and final acceptance tests for the ITER Divertor Remote Handling system.