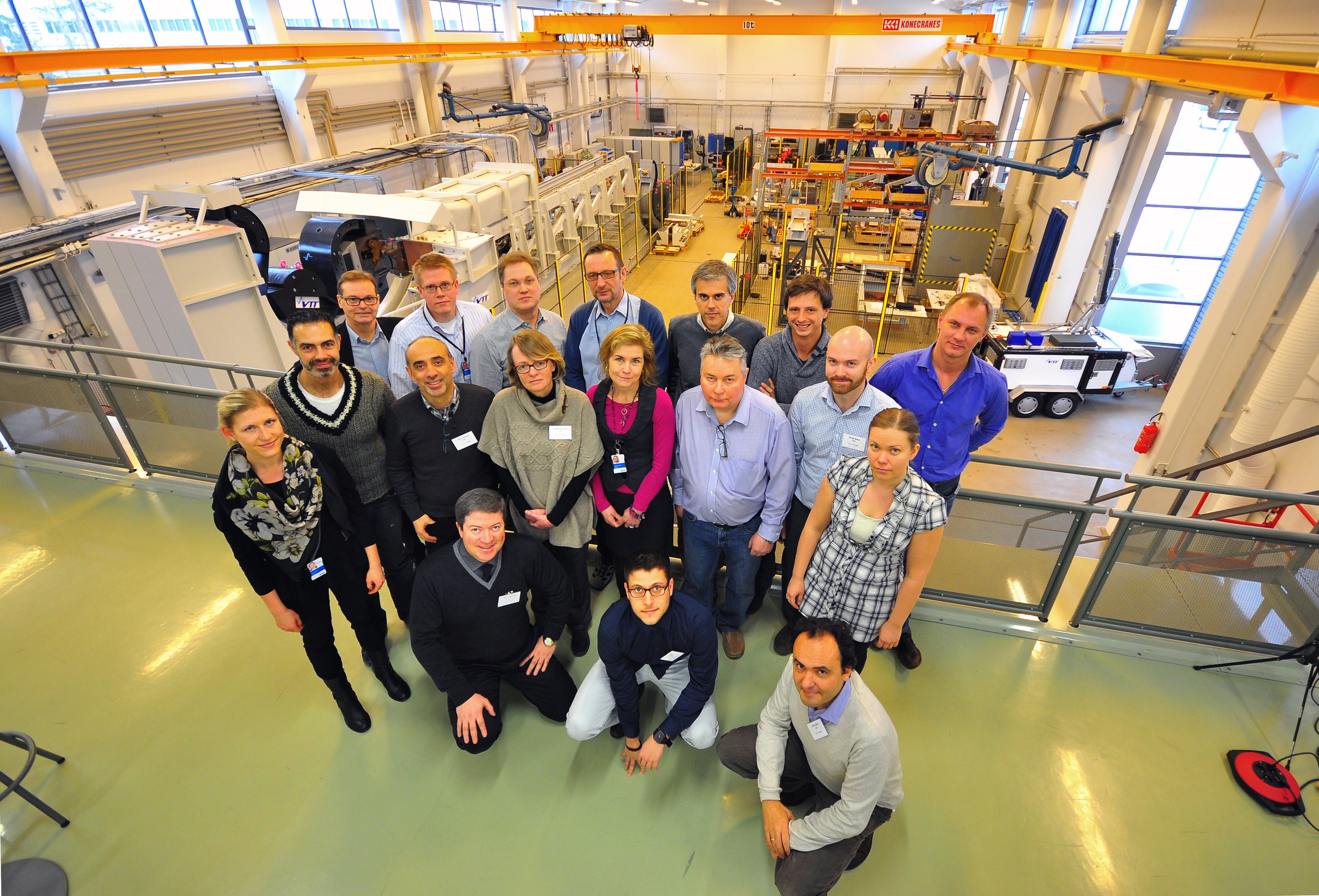

The event also carried a strong significance for the representatives of the European Domestic Agency for ITER, also present in the DTP2 hall. After years of European-financed R&D on the ITER remote handling systems (design, mockup fabrication and demonstrations), the time had come to pass the challenge on to industry — in June 2014, Europe signed a EUR 40 million

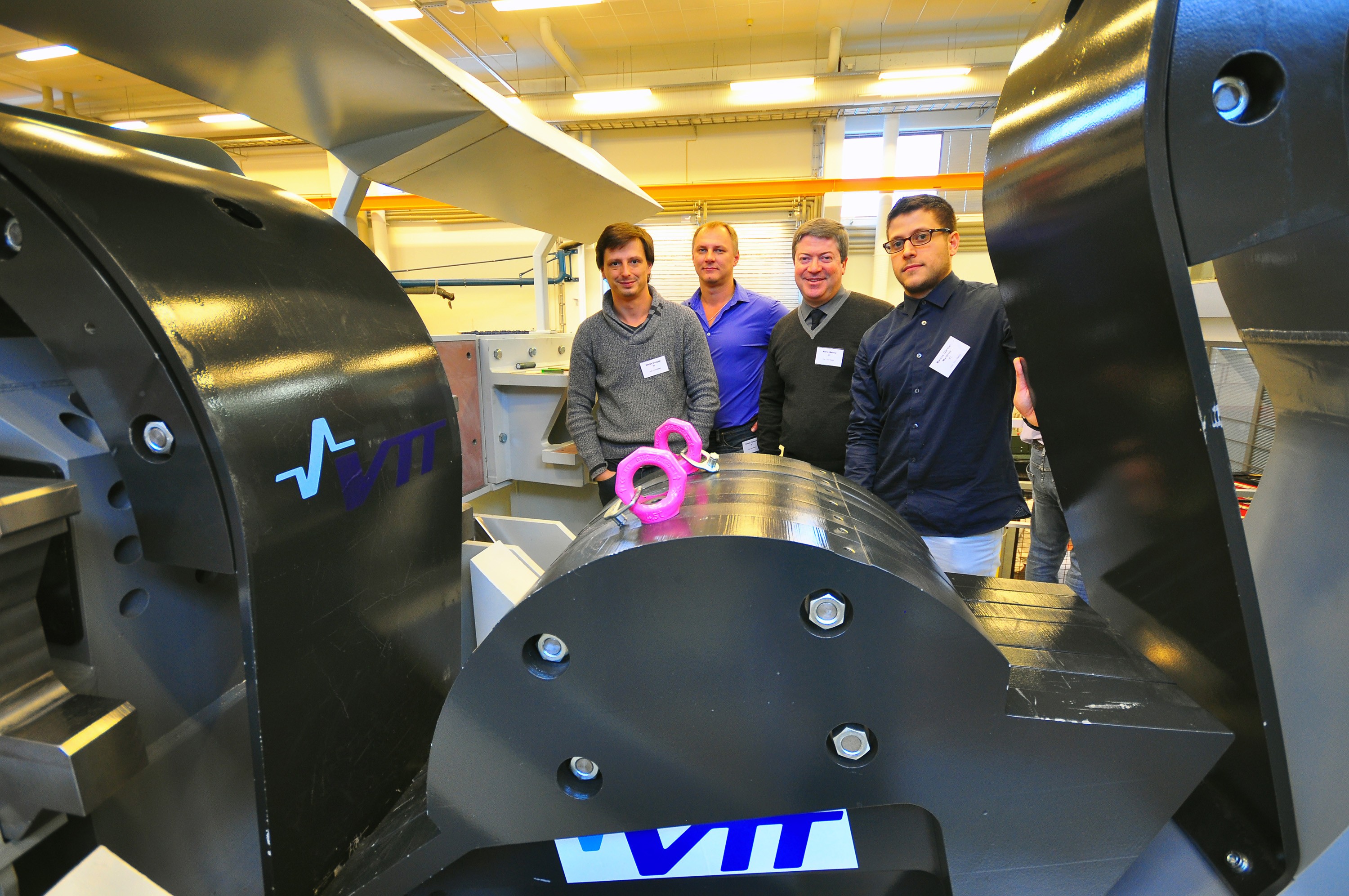

contract with a partnership of laboratories and companies led by Assystem(2) for the design, manufacturing, delivery, on-site integration, commissioning and final acceptance tests for the ITER Divertor Remote Handling system.

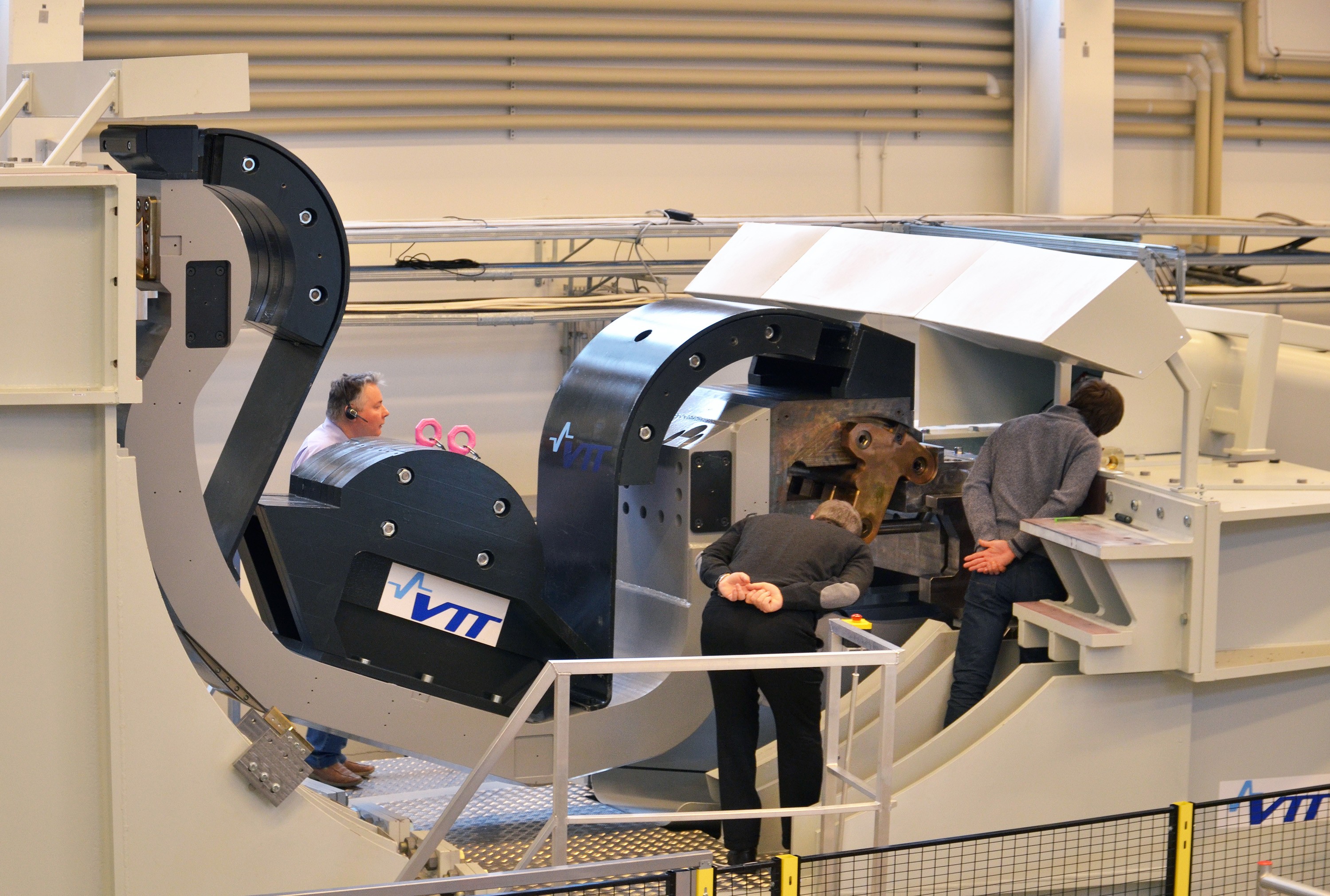

In the DTP2 control room, a few steps away from the 20-metre-long cassette multifunction mover, VTT senior researcher Hannu Saarinen sits, eyes riveted to an array of screens. To his left, a large virtual image shows the progression of the cassette inside the narrow tunnel of the port; on smaller screens, below, numbers and figures scroll endlessly. Without a way to fit a camera into the tunnel, all information is based on sensors and virtual reality; without it, operators would be blind. "More than 80 percent of the operation is pre-programmed," explains Saarinen. "We use the joystick only for small adjustments."

Saarinen and his colleague Vesa Hämäläinen are sitting only a few metres from activity on the mockup. But they could as well be separated by millions of kilometres of space or thousands of leagues of ocean depth. "This has been one of the biggest challenges of the operation: working with pure models without any visual connexion," says VTT Executive Vice-President Jouko Suokas. "But it has been an excellent platform to increase our competency in virtual reality and control software. This expertise is now being transferred to industry, which was one of the key reasons for our involvement in this project."

In the "laboratory conditions" provided by DTP2 in Tampere, the operation was a model of perfection. Years before the 54 divertor cassettes will be inserted into the ITER vacuum vessel, work is beginning now so that—in the industrial environment of ITER assembly—the same level of perfection is achieved.

(1) Assystem leads a team of well-known experts in the remote handling field, comprising the Culham Centre for Fusion Energy, CCFE (UK); Soil Machine Dynamics Ltd, SMD (UK); VTT Technical Research Centre (Finland); and Tampere University of Technology, TUT (Finland).