First magnet in place

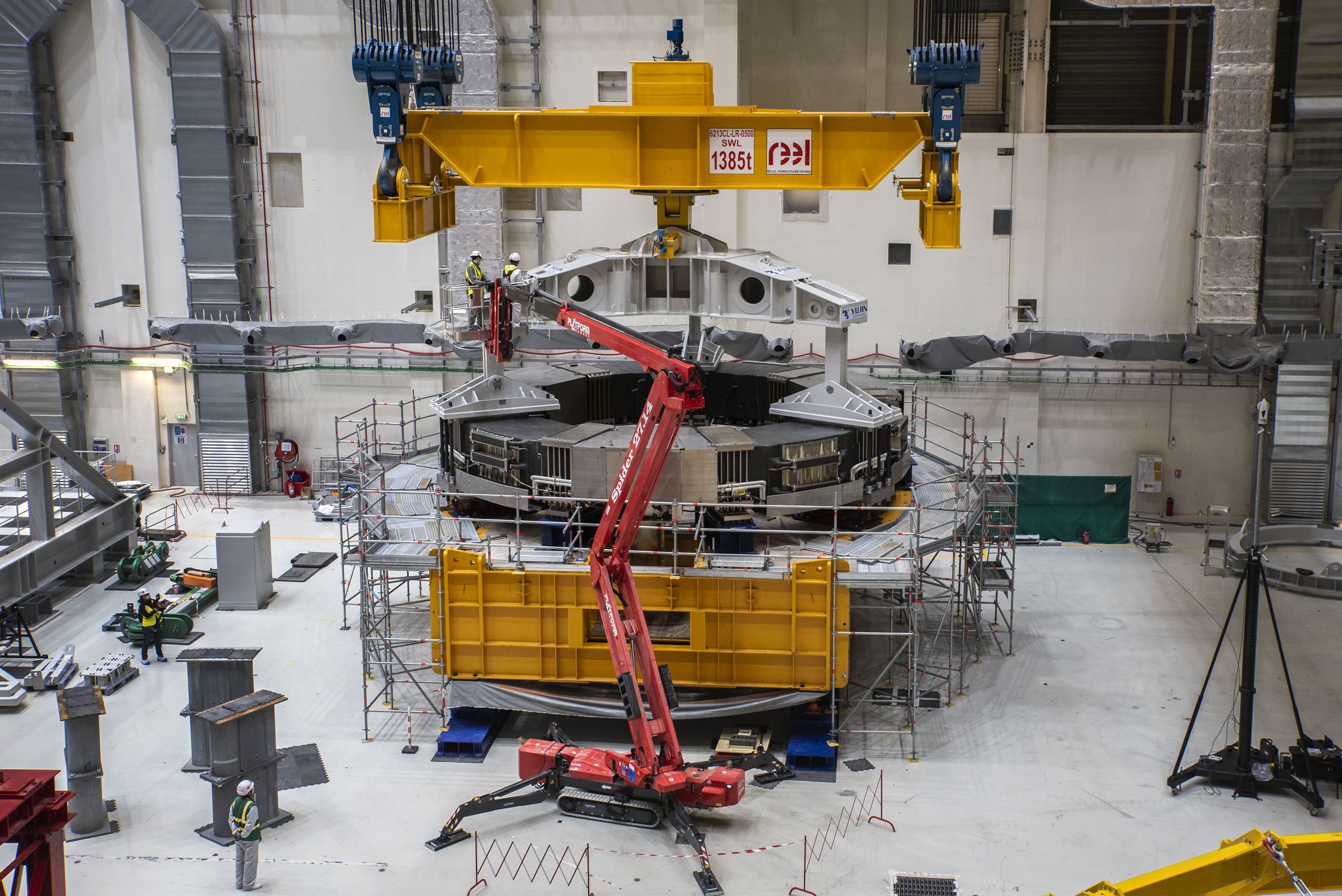

When it travelled the ITER Itinerary last year, or during cold tests in the onsite winding facility, poloidal field coil #6 (PF6) felt rather large and massive. Although only 10 metres in diameter—compared to 24 metres for the largest of the six ring coils that circle the machine—the 330-tonne coil is particularly thick and bulky. But everything is relative. On Thursday 21 April when the coil was extracted from its support frame and lifted 25 metres overhead to be transferred to the assembly pit, the perception of its size changed dramatically: dwarfed by the huge volume of the Hall, it suddenly felt small—a steel frisbee slowly gliding through immensity.

PF6 is thick and heavy because it has more conductor layers than any other poloidal field coil and more conductor turns per layer. Sitting at the bottom of the machine, it is known as the "divertor coil," whose main function is to create the null field point that allows the removal of helium ash from the plasma. "In order to have zero magnetic field at the divertor null field point, the bottom magnet needs to generate a field equivalent in intensity to the one created by the plasma current—but with an opposite polarity," explains Nello Dolgetta of the ITER Magnet Section. "And this is the reason why, despite its relatively small diameter, PF6 is so heavy. Since the magnetic field is defined by the intensity of the electric current times the number of conductor turns, we have 30 to 50 percent more coil turns in PF6 than in the other poloidal field coils."

PF6 is a European procurement that, for organizational reasons, was manufactured in China by the Institute of Plasma Physics of the Chinese Academy of Sciences (ASIPP). "The problem we faced was that the first two coils to be installed, PF6 and the much larger PF5, had to be delivered at almost at the same time," explains Alessandro Bonito-Oliva, the Magnets Programme Manager at the European Domestic Agency Fusion for Energy. "As there was not enough space in the on-site winding facility to install two parallel production lines we discussed the issue with different Domestic Agencies and eventually determined that ASIPP was the best potential supplier."

Finalized in September 2019, the coil was seven years in the making. In Alessandro's words, it was a "collective achievement of Europe and China, working together with the ITER Organization to manufacture a first-of-a-kind component that presented a number of technical and organizational challenges."

The coil shipped from Hefei by barge in March 2020, sailed the Yangtze River to Shanghai, and reached the French port of Fos-sur-Mer in June. In order to allow for transport to the ITER construction site, a few portions of the ITER Itinerary had to be adapted or enlarged.

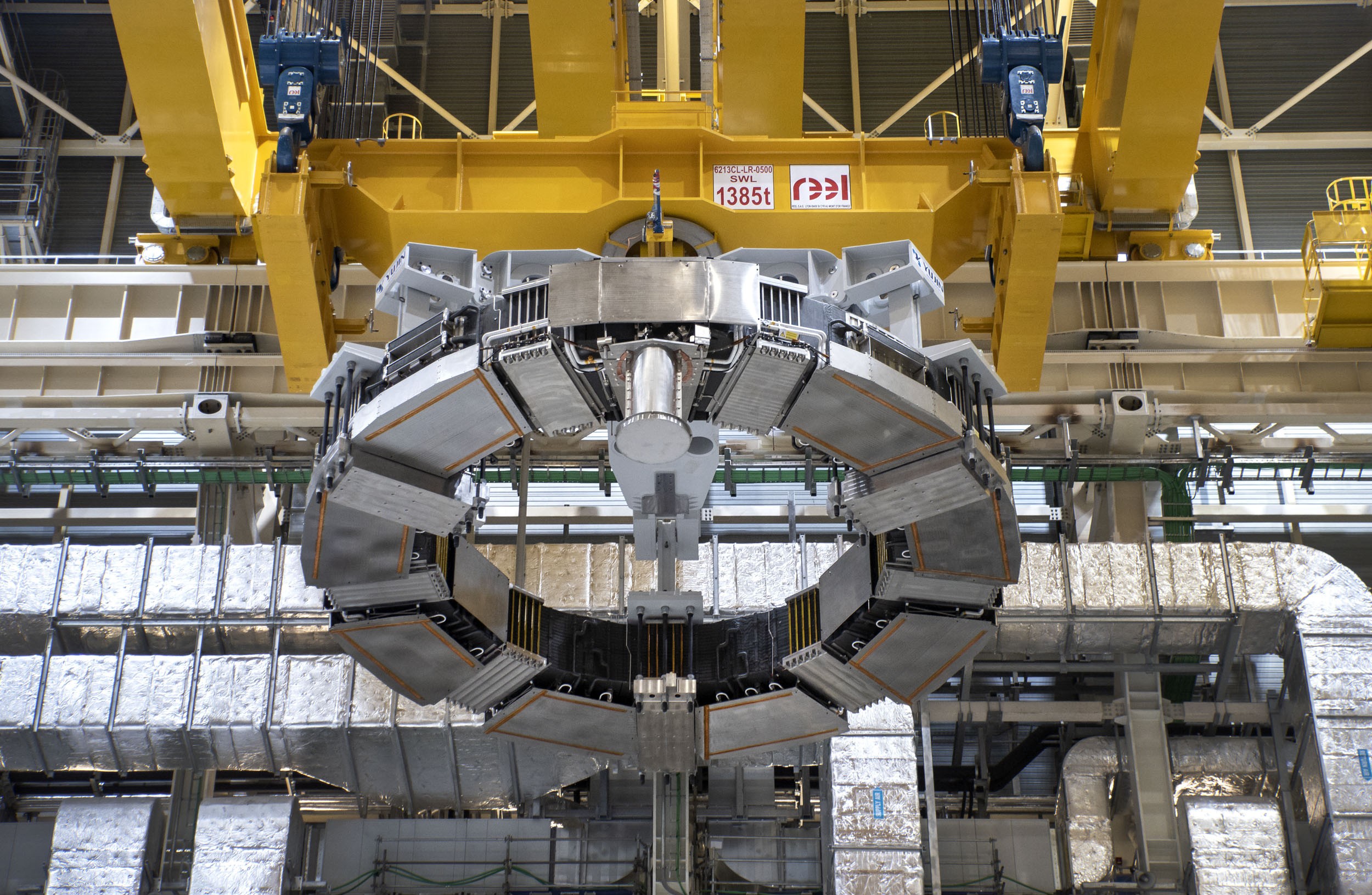

The lifting, handling and installation of PF6 on 21 April 2021 was an eight-hour operation that required a complex rigging system capable of rotating the coil and positioning it to within 4 millimetres of tolerance. Composed of a 92-tonne dual crane heavy load beam (also used to lift the first vacuum vessel sector), a 42-tonne lifting frame, and a set of lifting adapters, the rigging brought the total load to approximately 480 tonnes—the third heaviest lift after the cryostat base and vacuum vessel sector #6, transported in May 2020 and April 2021 respectively.

On the day before the operation the team performed a lift test, and assessed the risk of not compensating the slight imbalance in the component's centre of gravity caused by a one-tonne feeder interface that sticks out from under the coil on one side. "The slight tilting of the coil during the lift did not exceed one degree and remained within tolerance," explains Jens Reich, the head of the Ex-Vessel Delivery & Assembly Division, as the coil settled on its supports in the late afternoon. "Everything went perfectly smoothly."

Coming after the cryostat base, cryostat lower cylinder, lower cryostat thermal shield and first vacuum vessel sector, the installation of PF6 was the fifth heavy lift of the machine assembly sequence. "The lessons we learned are many," adds Jens. "From an organizational point of view, it was very important to precisely define who is responsible for what at each point of the installation sequence. A strong interaction with our contractors is a pre-condition to avoid any misunderstandings. But above all, what the experience confirmed is the absolute need to test and rehearse, especially when we have to operate such a complex rigging as the one we used in the PF6 operation and will use again for PF1 and the 1,000-tonne central solenoid."

PF6 will remain on its temporary supports for a few years, pending the installation and welding of all nine vacuum vessel sub-assemblies. Once this is completed, the hydraulic system of the temporary supports will slightly lift the coil to anchor it to the toroidal field coil superstructure. A similar sequence will be followed for the next poloidal field coil (PF5, 17 metres in diameter), which is due inside the pit this summer.

See a report on the Fusion for Energy website.