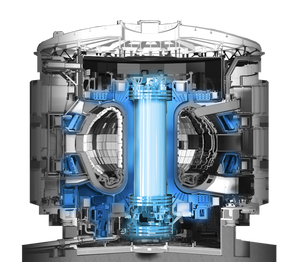

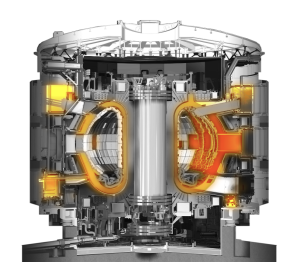

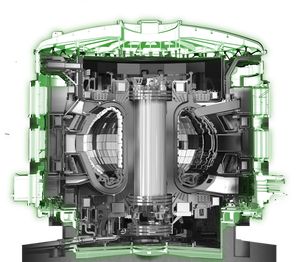

Divertor

Situated at the bottom of the vacuum vessel, the divertor extracts heat and ash produced by the fusion reaction, minimizes plasma contamination, and protects the surrounding walls from thermal and neutronic loads.

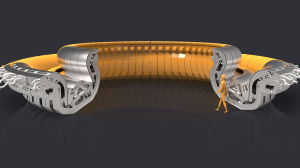

Each of the divertor's 54 "cassette assemblies" has a supporting structure in stainless steel and three plasma-facing components: the inner and outer vertical targets and the dome. The cassette assemblies also host a number of diagnostic components for plasma control and physics evaluation and optimization.

The inner and outer vertical targets are positioned at the intersection of magnetic field lines where particle bombardment will be particularly intense in ITER. As the high-energy plasma particles strike the vertical targets, their kinetic energy is transformed into heat and the heat is removed by active water cooling.

The heat flux sustained by the ITER divertor vertical targets is estimated at 10 MWm² (steady state) and 20 MWm² (slow transients). Tungsten, with the highest melting point of all the metals, has been chosen as the armour material following an international R&D effort, encouraging experimental results, and successful prototype testing.

The 54 ten-tonne cassette assemblies of the ITER divertor will be installed—and also replaced at least once during the machine's lifetime—by remote handling.

Divertor targets

The plasma-facing components of the ITER divertor will be exposed to a heat load that is ten times higher than that of a spacecraft re-entering Earth's atmosphere (10-20 MWm²). To ensure the performance and manufacturability of these critical components, qualification activities on the ITER divertor plasma-facing components have been underway for years.

To demonstrate that the tungsten components can withstand the demanding thermal conditions of the ITER machine, full-scale prototype sections of the plasma-facing components undergo testing in a high-heat flux test facility specially conceived and built for ITER (the Divertor Test Facility in Russia). Experiments to test the melting behaviour of tungsten have been run on the JET tokamak (UK) and the WEST project (a modification of the Tore Supra tokamak in France) will contribute key insight into the steady state operation of a tungsten divertor and its impact on plasma performance.

The other components

Please note that all images are for illustrative purposes only.