All ring-shaped magnets now "home" at ITER

Of all the components and systems that Russia contributes to ITER, poloidal field coil #1 (PF1) is the most massive and one of the most complex. Measuring nine metres in diameter and weighing approximately 160 tonnes, it is the smallest of the six ring-shaped magnets that circle the ITER Tokamak and the only one that is not procured by Europe.

PF1 is not, by far, the heaviest of the 141 HELs (Highly Exceptional Loads) that have travelled the ITER Itinerary since January 2015. It is, however, one of the widest and—as a consequence—one of the most difficult to steer through plane-tree-lined roads, over bridges and through the extremely narrow passage between two small cliffs a few kilometres before the ITER construction site. Due to these challenges, it took the convoy four nights instead of the standard three to cover the whole length of the 105-kilometre-long ITER Itinerary.

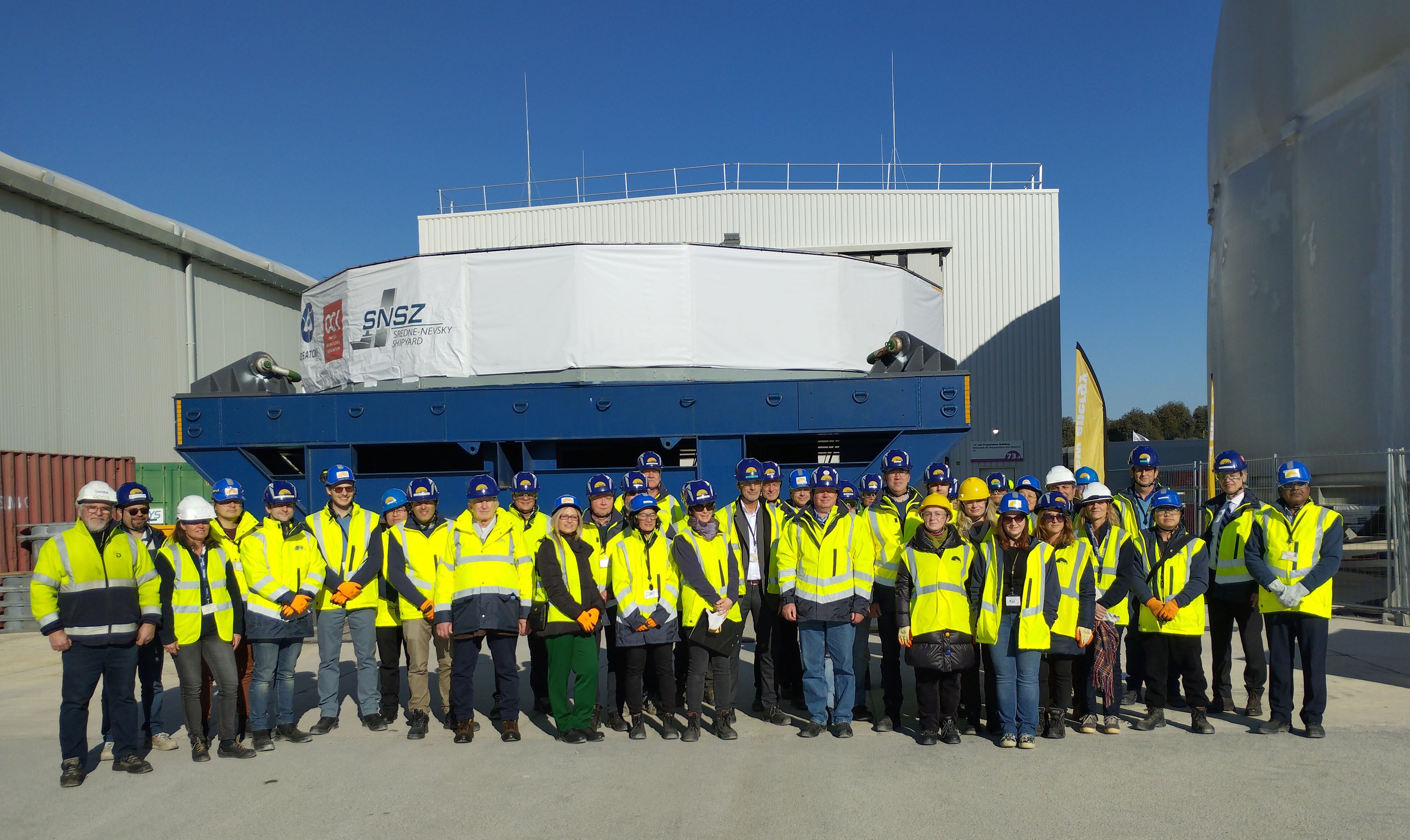

Like each HEL transport operation, the PF1 convoy relied on complex logistics involving men and machinery—9 drivers, navigators and mechanics to operate the 288-wheel self-propelled trailer and the powerful pulling and pushing tractors; a team of 14 people charged with removing road signs and other obstacles on the trailer's trajectory (and putting them back in place after the convoy's passage); and 70 officers from the dedicated protection group of the French Gendarmerie.

The arrival of PF1 on the construction site marked a significant milestone for the ITER Project, as all seven Members have now delivered at least one of the major components they are responsible for.

Speaking from Russia on behalf of Rosatom Director-General Alexey Likhachev, Anatoli Krasilnikov, Head of the Russian Domestic Agency, described ITER as "a vivid example of the closest international collaboration," of which Russia was "an integral part." After a quick update on project progress by ITER Head of Communication Laban Coblentz, Krasilnikov added a personal and emotional note, saying: "This is a great event for us today, but not the final, not the last one. We will meet each other many, many times for similar events, and it will be very important to demonstrate that fusion is a reality."

For ITER Director-General Pietro Barabaschi, the delivery of the PF1 magnet sent the strong message that "the ITER Organization and the Domestic Agencies are steadily continuing to deliver on their commitments for the construction of the ITER research facility in an integrated way," and that despite inevitable difficulties, "we will succeed, build the ITER Tokamak and deliver unprecedented research capabilities to support the realization of fusion power."

With PF1 in protective storage, all six poloidal field coils are now safely "home": PF6 and PF5 already installed in the Tokamak assembly pit, PF2 stored, and PF3 and PF4 in the last stages of fabrication and testing in Europe's Poloidal Field Coils Winding Facility on site.

Click here to view a video of the transport and delivery of PF1.