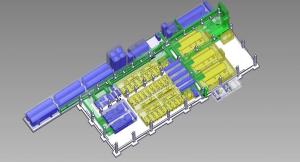

The LN2 plant will provide liquid nitrogen cooling for the liquid helium plant and the 80 K helium loop, as well as storage for the LN2 inventory. The plant is made up of two nitrogen refrigerators, two 80 K helium loop refrigerators, helium and nitrogen storage, helium recovering and purification, and heaters.

"The ITER cryogenics system is a closed loop system," explains Emmanuel Monneret, Technical Responsible Officer for the Procurement Arrangement and member of ITER's cryogenics team. "We need the capacity to store the entire inventory of gases during maintenance periods, when the ITER magnets are returned to room temperature. The inventory (25 tonnes of helium and 160 tonnes of liquid nitrogen) is recovered and stored in warm (300 K) and cold (4 K and 80 K) tanks until needed again for operation." (The tanks are shown in blue in the above diagram.)

In addition, two giant 80 K quench tanks are reserved for the recovery of helium in case of a magnet quench—a situation where superconductivity is lost due to a local temperature rise in the magnets.

The European Domestic Agency (EU-DA) is responsible for the detailled design, manufacturing, installation and testing of the LN2 plant and auxiliary systems. "Two aspects of this procurement are 'out of the ordinary,'" says Emmanuel. "First, the storage designed for quench recovery will be the largest of its kind. And second, the plant will use a helium gas compression technique—centrifugal compression—that has never been used before on this scale. Standard helium oil screwed compressors can't be used in this case because of the compression ratio and flow volume required by the ITER machine."