A prize-winning story of metallic melting in tokamaks

An obvious property of metals is that they melt, and metallic components directly facing the plasma are one thing ITER has a whole lot of. A total surface area of about 800 m² to be more precise. What happens when they do melt was in the spotlight at the recent 29th IAEA Fusion Energy Conference when a paper focusing on the physics of transient-heat-pulse-induced melting was awarded the prestigious Nuclear Fusion prize for 2023.

In contrast, tungsten is a remarkable material in terms of robustness and has the highest melting point (3422 °C) of all known elements, an elevated energy threshold for sputtering, and negligible fuel retention issues in comparison with beryllium. These are the principal reasons for deploying it in the divertor region, where steady heat and particle fluxes are extremely high. It does, though, have one serious drawback: as a very high atomic number material, only very small concentrations will be tolerable in ITER's fusion plasmas before the burn is compromised. Nevertheless, tungsten is the most widely favoured candidate in most magnetic confinement fusion reactor designs, and the long-term objective of ITER has always been to operate eventually with tungsten as sole plasma-facing material after starting first nuclear operations with beryllium main wall armour to ease the pathway to burning plasmas. In view of technical issues which have arisen during machine construction, this long-term plan is now being brought forward in a new proposal currently under development at the ITER Organization to go "full-tungsten" from the very beginning of operations. A review of this proposal was the sole objective of last month's STAC meeting (ITER Council Science and Technology Advisory Committee) held at ITER Headquarters.

But even the lofty tungsten melting temperature is no match for the reactor-scale plasmas ITER will explore. Thermal energies in ITER fusion plasmas (up to ~350 MJ) and energy stored in the magnetic field (up to ~600 MJ) when operating at high plasma current dwarf those accessible in smaller research tokamaks. Uncontrolled releases of this energy—for example during fast transient magnetohydrodynamic activity and plasma disruptions, or in cases of slow power flux excursions to the divertor targets—can melt even tungsten surfaces. This is a result of the specific character of magnetically confined plasmas: the energy is focused onto very local areas due to the geometry of the magnetic field so that energy densities can be extremely high.

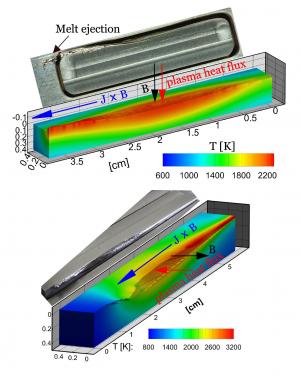

In fact, tungsten melting in tokamaks is rather different than what would be found in most other situations. At melting temperature, tungsten is a very strong electron emitter (the phenomenon of thermionic emission). When a melt layer forms on a tungsten plasma-facing component, thermionic electrons emitted from the surface towards the plasma leave behind a positive charge, which is neutralized by an electric current (the "replacement current") flowing through the component and the molten layer. These currents can be enormous, easily in the range of millions of amperes per square metre. If they flow across the strong tokamak magnetic fields, Lorentz forces can then drive very rapid melt acceleration (hundreds of metres per second squared). Not only does the surface melt, but the melt layer can be swept over large surface areas. What then does the affected material surface look like topologically, how resilient will it be to subsequent power loading and how much damage can be tolerated before repair is required?

Answering such questions has been a priority at the ITER Organization in recent years. The tokamak community has been long been aware of the issue, but it has lacked a quantitative, experimentally benchmarked framework to make predictions at the reactor scale. Pioneering experiments on deliberate tungsten melting and melt motion under steady heat loading were performed in the TEXTOR tokamak nearly a decade and a half ago, but it was only in 2014 that the first experimental demonstration of "controlled" rapid transient tungsten melting in a tokamak was achieved at JET in a series of tests performed in collaboration with ITER. Numerical simulations were attempted of both the TEXTOR and JET experiments using a melt code (MEMOS-3D) developed at the Karlsruhe Institute of Technology (KIT). Results were reasonable, but something better was required to be confident of extrapolations to ITER. Enter a team led by 2023 Nuclear Fusion prize laureate Prof. Svetlana Ratynskaia from the Space and Plasma Physics Division of the Royal Institute of Technology, Stockholm (KTH). They were approached by the ITER Organization in January 2016 at an International Tokamak Physics Activity (ITPA) Topical Group meeting in Frascati, Italy, and asked to consider joining the effort to improve the framework for melt predictions. Experts in many detailed theoretical aspects of plasma-material interactions, but not previously involved in tokamak melt simulations, they accepted the challenge and what followed has been an outstanding example of how the fusion research community can mobilize to address key issues for ITER.

And the work goes on. The physics models describing melting and melt motion have been subject to yet more experimental tests in the past two years on the ASDEX Upgrade, WEST and DIII-D tokamaks, now coordinated through a multi-machine ITPA activity. In parallel, the KTH team has used the improved understanding gained over the years since their first involvement to produce a completely new, modern and flexible modelling tool (the MEMENTO code) which is being applied successfully to the interpretation of the most recent melt experiments and will be applied to others still being planned. This new framework is also now being employed as the main predictive tool for the assessment of gross topological erosion due to transient-induced armour melting on ITER, closing the loop on this truly global effort in support of ITER and providing a key modelling framework for similar assessments at the fusion reactor scale.

Journal article reference: Ratynskaia, S., Thorén, E., Tolias, P., Pitts, R.A., Krieger, K., Vignitchouk, L., Iglesias D., the ASDEX-Upgrade team, the JET contributors, and the EUROfusion MST1 team (2020). Resolidification-controlled melt dynamics under fast transient tokamak plasma loads. Nuclear Fusion, 60. https://iopscience.iop.org/article/10.1088/1741-4326/abadac