Perfecting the pellet

The Blanket and Fuel Cycle group in ORNL's Fusion Energy Division is conducting research for the design and construction of ITER's shattered pellet injection disruption mitigation system in collaboration with US ITER and the ITER Organization.

"We have the infrastructure, we have the knowledge," said R&D engineer and pellet injection scientist Trey Gebhart, who is leading the effort. "We know what needs to be looked into to provide the most reliable design."

Learning to tame ITER disruptions, "would be a big deal for sure," explained physicist Dave Rasmussen, who oversees the pellet injection and disruption mitigation teams for US ITER. "ITER's plasma is at the scale of a fusion reactor that could inform future fusion power plants. It would be a great achievement to resolve this issue along the way."

ORNL pioneered shattered pellet injection technology a decade ago by building on the lab's longtime expertise in pellet injection—systems that shoot pellets of deuterium, tritium or hydrogen fuel into the plasma of fusion devices.

Shattered pellet injection systems, however, don't fuel plasma. Rather, they shut down the plasma when instabilities occur that threaten the plasma-facing surfaces of the machine walls. This process is called disruption mitigation.

Over the years, ORNL has supplied shattered pellet injection systems to fusion experiments around the world. Now these experts are helping adapt that technology to the much larger scale of ITER, the world's largest tokamak by far.

About the size of wine corks, ITER shattered pellet injection pellets will be more than 15 times larger than those used in today's tokamaks. The ORNL team is currently testing 28-mm-diameter pellets and will soon begin testing 23-mm pellets.

"Scaling from small pellets to the ITER-size pellets introduces a lot of challenges," Gebhart explained.

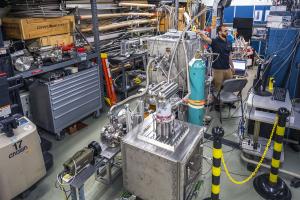

Gebhart designed a special test bed to tackle those challenges, from the frigid formation of pellets to their fiery finale.

Just as larger ice cubes freeze more slowly, larger pellets take more time to desublimate. In Gebhart's first attempt, it took about an hour—twice as long as ITER requires. The team gave those larger pellets a head start by devising a special precooling heat exchanger using liquid nitrogen at -196 degrees Celsius, cutting pellet formation time by half.

Desublimating deuterium, an istope of hydrogen composed of one proton, one electron and one neutron, is much easier, however, compared to hydrogen—the preferred material for ITER.

ORNL distinguished staff scientist Larry Baylor, who leads the Blanket and Fuel Cycle group, explained the problem. As pellet gas chills inside a pipe, molecules at first stick to the inside surface and desublimate. The pellet forms layer by layer from the outside in, eventually filling the whole space in the pipe. But hydrogen, a poor thermal conductor, doesn't desublimate as well as deuterium.

To help solve this problem, Baylor has been measuring and modeling this "condensation coefficient" for hydrogen, which previously had not been well understood.

"As the cylindrical ring of material gets thicker, these molecules no longer stick as well when they get on the surface," Baylor explained. "They bounce off because they don't lose all their thermal energy, because of this heat transfer problem."

Shooting pellets down a precise path is another challenge. Because the tubes that direct the pellets into the tokamak will be unusually narrow at ITER, the flying pellets can deviate no more than one degree from an arrow-straight path. The bigger ITER pellets will require more force to send them into the tokamak. Apply that force too fast, however, and the pellet breaks.

"You have to home in on this narrow Goldilocks spot that will get your pellet out intact," Gebhart explained.

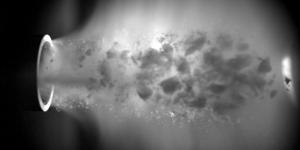

Another engineering challenge awaits at the other end of the flight path. By design, the pellets slam into a curved section of the tube wall at 250 metres a second, breaking into pieces. Those fragments will disperse across the plasma, cooling it down as the plasma expends energy stripping electrons off the cold atoms.

The ORNL team is now investigating how pellet speed, pellet material and tube angle affect the all-important fragment distribution. They have discovered clues from some interesting sources, including a World War II-era study of shrapnel.

"We use a statistical fragmentation model that was actually derived in the 1940s for understanding how grenades fragment when they explode," Gebhart explained. "Pellet material is very brittle, much like some metals."

All of these elements can help to improve the system's performance.

"Previously, everything was just, 'Shoot the pellet, you get what you get, and it does its job,'" Gebhart said. "Now, we are slowly learning that we can tweak it to produce better results."

See the original story at US ITER.