Last major assembly contract signed

Following competitive global tender campaigns managed by ITER's Procurement & Contracts Division, two international groups—one incorporated as a consortium and the other as a commercial partnership—have been awarded contracts for installation activities inside of the Tokamak Complex.

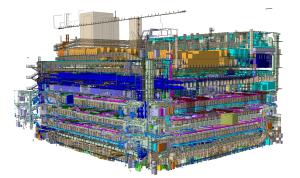

These phased, long-term contracts will cover the pre-assembly and installation of the millions of components that make up the plant systems supporting the ITER machine, including fuelling, vacuum, diagnostics, cooling, power, and heating. The two assembly contractors for the Tokamak Complex will carry out similar types of installation tasks, notably mechanical and piping works (vessels, piping systems, heat exchangers, pumps, motors; cable trays and cable pulling; wave guides; piping thermal installation; pressure tests), and electrical- and instrumentation-and-control-related works (DC busbars, switching equipment, power cables, I&C cables and cabinets).

- The TCC1 assembly contract—for the installation of heating and current drive, diagnostics, fuelling, secondary cooling, and vacuum components—was signed in December 2019 by the ITER Organization and the Fincantieri Consortium (Fincantieri S.p.A., Fincantieri SI S.p.A., Delta-ti Impianti S.p.A., Comes S.p.A.)

- The TCC2 assembly contract—for the installation of primary machine cooling water, test blanket module equipment, some vacuum pipework, vacuum vessel pressure suppression—was signed in December 2020 by the ITER Organization and the META SNC (Ponticelli Freres SAS, Cobra Instalaciones y Servicios SA, and Empresarios Agrupados Internacional SA.).

These contracts are the last major assembly and installation contracts planned for first-phase ITER assembly. (Two major contracts for Tokamak assembly, as well as five "balance of plant" contracts are already underway.)

"The Procurement & Contracts teams have worked in very close collaboration with the Legal, Finance, Project Control, Quality and Nuclear Safety teams to prepare, develop, select and negotiate the two Tokamak Complex contracts. The two partners were chosen based on excellent technical capability at a competitive price, and we now need to collectively deliver on these promises through a deep collaboration between the teams at all levels. Such effective collaboration doesn't happen overnight; it requires a common sense of purpose that's aligned with the long-term business interests of all the companies involved," commented Christophe Dorschner, head of Procurement & Contracts Division at ITER.

Within the ITER Organization, the contracts are managed by Machine Assembly Planning & Contract Management Section (part of the Machine Construction Department) in close collaboration with Tokamak Complex Division.

Each contract is broken into phases, with detailed works assigned progressively to the contractors through ITER Organization work packages. The execution of assembly works will take place under the overall responsibility of the ITER Construction team and the day-to-day management of ITER's Construction Management-as-Agent, MOMENTUM.

Although the works will be concentrated in the Tokamak Complex (outside of the Tokamak machine boundary), some activity will also take place under these contracts in the Radiofrequency Building and Assembly Hall. Part of the expected challenge will be the coordination on the ground between Tokamak Complex contractors, contractors to the European Domestic Agency who continue to progress the installation of building services, and other dedicated teams carrying out the installation of multi-process cryolines, busbars and magnet feeders.

For more information on the ITER strategy for machine and plant assembly, see this article.