"Through all of these activities, the main point is that we pioneered traceability, recording all activities prior, during and post manufacturing with approved formats of documents," affirms Chang Ho Choi, who leads the Vacuum Vessel Project Team. "This is important because vacuum vessel procurement involves four ITER Members, and that final assembly will be carried out by ITER Organization contractors on site. Proper documentation, therefore, will make everyone's job easier. Our collaboration is very well established at this point, after 53 monthly meetings over the years and 10 on-site meetings that included a lot of knowledge sharing and visits to manufacturing facilities. This gives us confidence as we head toward the most important moment of all: machine assembly."

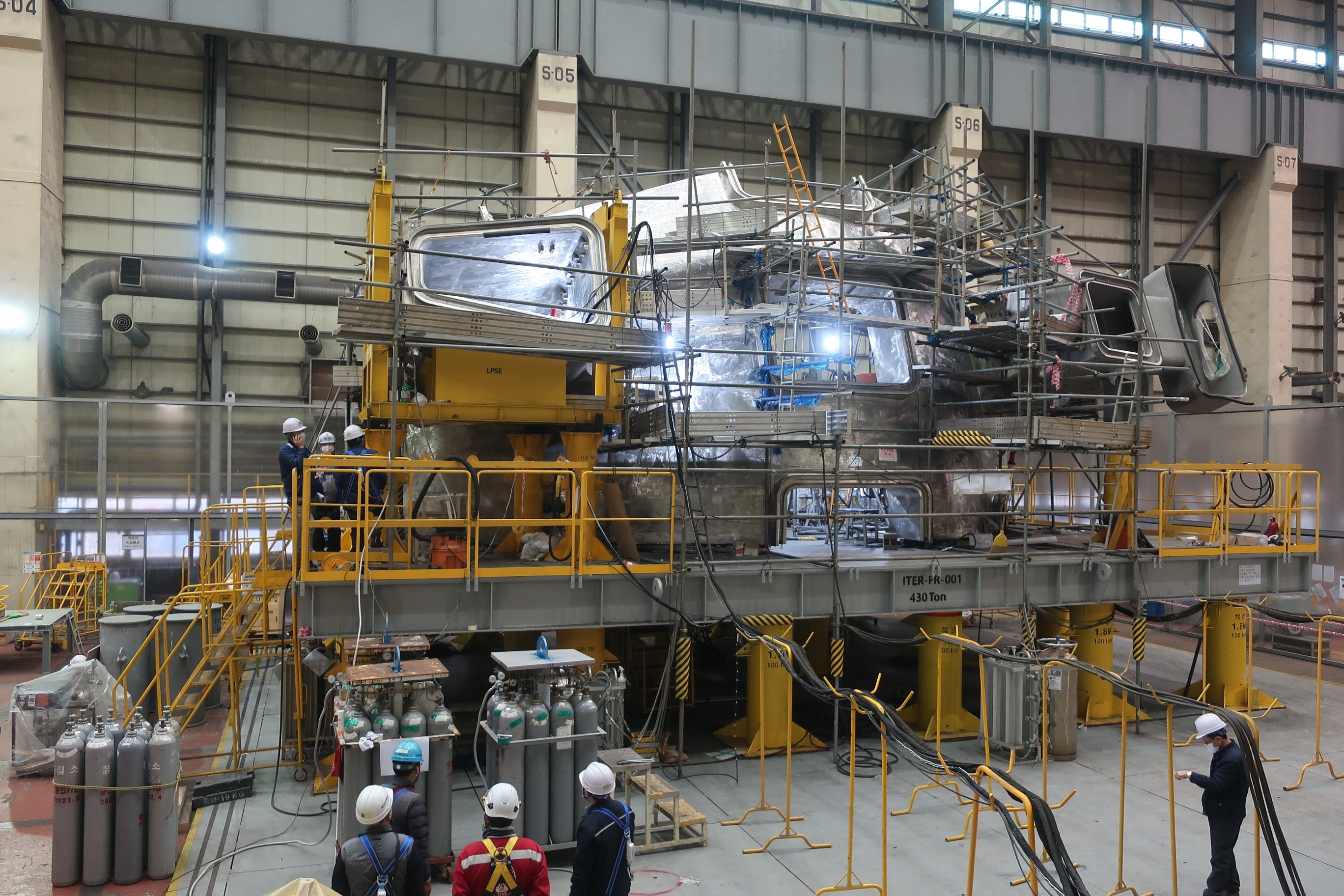

When ITER vacuum vessel sector #6 arrives at ITER this summer, it will be brought into the Assembly Building and transferred by overhead crane to a laydown area. After a final helium leak test¹ and site acceptance test, the component will be ready for handover to ITER Organization assembly contractor responsible for the vessel (

TAC2) for a series of installation activities (diagnostics, instrumentation and cable trays on the outer shell).

A

ceremony on 20 April at Hyundai Heavy Industries in Ulsan, Korea, was attended by Byungseon Jeong, First Assistant Minister, Ministry of Science and ICT; Young-seuk Han, President and CEO of Hyundai Heavy Industries; Sukjae Yoo, President of Korea's National Fusion Research Institute; Kijung Jung, Director General of ITER Korea; and more than 30 experts.

"Deep and close collaboration among ITER Korea, the European Domestic Agency Fusion for Energy, ITER Russia, and the ITER Vacuum Vessel Project Team is the key driving force of our achievement," explained Kijung Jung. "It allows the most challenging and complicated issues to be resolved and will lead our ITER Project to success."

¹ Due to international travel restrictions related to the global coronavirus crisis, the ITER Organization observer/quality control inspector could not be present for the pressure and leak tests. These acceptance activities will be performed again when the component reaches ITER.

² The Vacuum Vessel Project Team reunites staff from the European, Korean, Indian and Russian Domestic Agencies with staff from the ITER Organization in regular meetings to improve the overall efficiency of vacuum vessel procurement execution.

³ An Agreed Notified Body (ANB) is authorized by the French Nuclear Regulator ASN to assess the conformity of components in the pressure equipment category (ESPN).

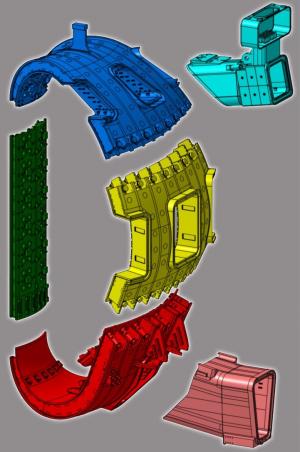

See the gallery below for more detail on the fabrication steps.