Home stretch for base and lower cylinder

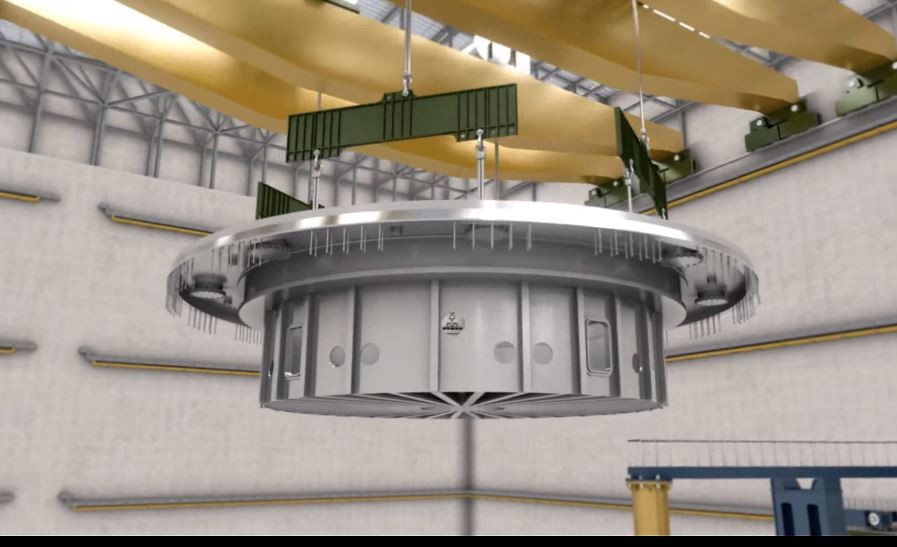

On large steel frames at either end of the Cryostat Workshop ITER's largest component—and the world's largest stainless steel high-vacuum pressure chamber—is taking shape. The 29 x 29 metre cryostat has two important functions in the ITER machine: it provides a vacuum environment to critical "cold" components (the magnets operating at 4.5 K and thermal shield operating at 80 K); and it has a structural role in supporting the mass of the Tokamak and transferring horizontal and rotational forces to the radial walls.

The assembly of the cryostat has been underway since September 2016, when teams of welding specialists began assembling the pie-slice-shaped segments of tier one of the base. Work began in 2017 on the lower cylinder and today, the fabrication of both lower sections has advanced to the final activity stage under Indian contractor Larsen & Toubro (manufacturing design, fabrication and assembly) and sub-contractor MAN Energy Solutions (welding).

The last seam welds are underway now on the lower cylinder, while the three parts of the base—lower sandwich, upper pedestal, and vertical shells—have been aligned for final welding and assembly.

See more detail in the gallery below.