A guide to work underway

Just like the ITER worksite, drone photography is also making progress. This view of the ITER platform is the sharpest and most detailed of all those we have published over the past decade. We have added labels and captions to showcase the ongoing work, some of it spectacular and visible, some performed in the depths of the buildings.

1 — Tokamak Building and Assembly Hall: As repair operations on vacuum vessel #7 and #6 are nearing completion in the Assembly Hall, the installation of heavy electro-mechanical equipment in the adjacent Tokamak Building and Tokamak assembly pit is mobilizing approximately 300 workers. Among the systems and structures being installed: piping for the cooling water system, platform construction in the drain tank room and in the L4 "vault", fuelling equipment, etc.

2 — Former Cryostat Workshop: The 5,000-square-metre workshop where the four sections of the ITER cryostat were assembled and welded now hosts the repair activities on vacuum vessel sector #8 and some thermal shield panels.

3 — Poloidal field coil winding facility: In this mighty European factory, four of the largest ITER poloidal field coils, ranging in diameter from 17 to 24 metres and weighing 200 to 400 tonnes, were manufactured and cold tested over a period of approximately ten years. The 49-metre-wide, 257-metre-long facility is now partially devoted to thermal shield panel repair and will host the toroidal field coil cold test facility.

4 — Coil storage: Whether D-shaped or ring-shaped, the ITER superconducting coils are massive components that, ahead of their installation in the Tokamak assembly pit, require a large amount of storage space.

5 — Cryobridge: In order to reach clients inside the Tokamak Building, cooling fluids produced by the ITER cryoplant flow through many kilometres of highly sophisticated piping called cryolines. Departing from and returning to the cryoplant, the cryolines must pass over an industrial bridge more than 10 metres above the ground—the cryobridge. The installation of cryoline spools is approximately 50% complete.

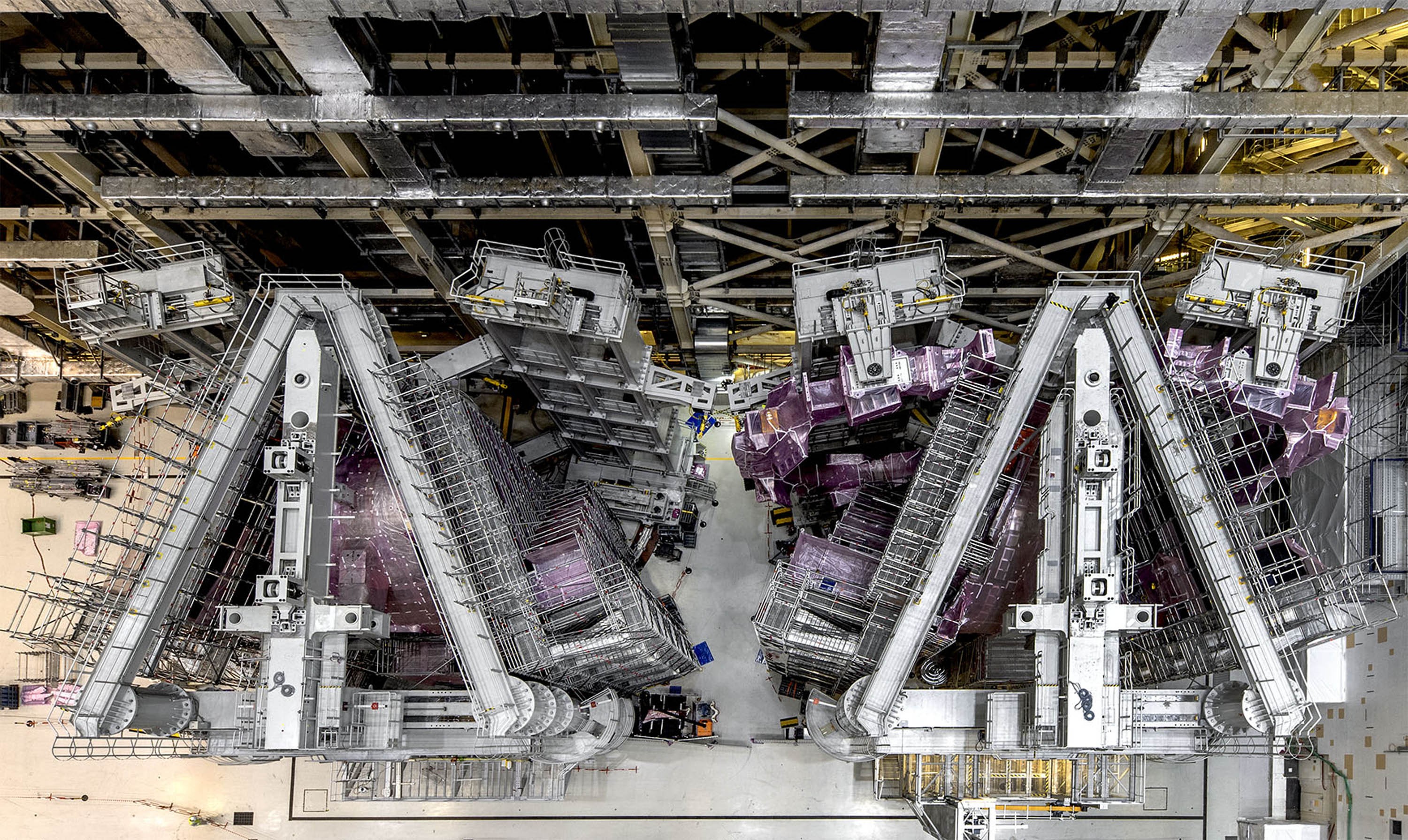

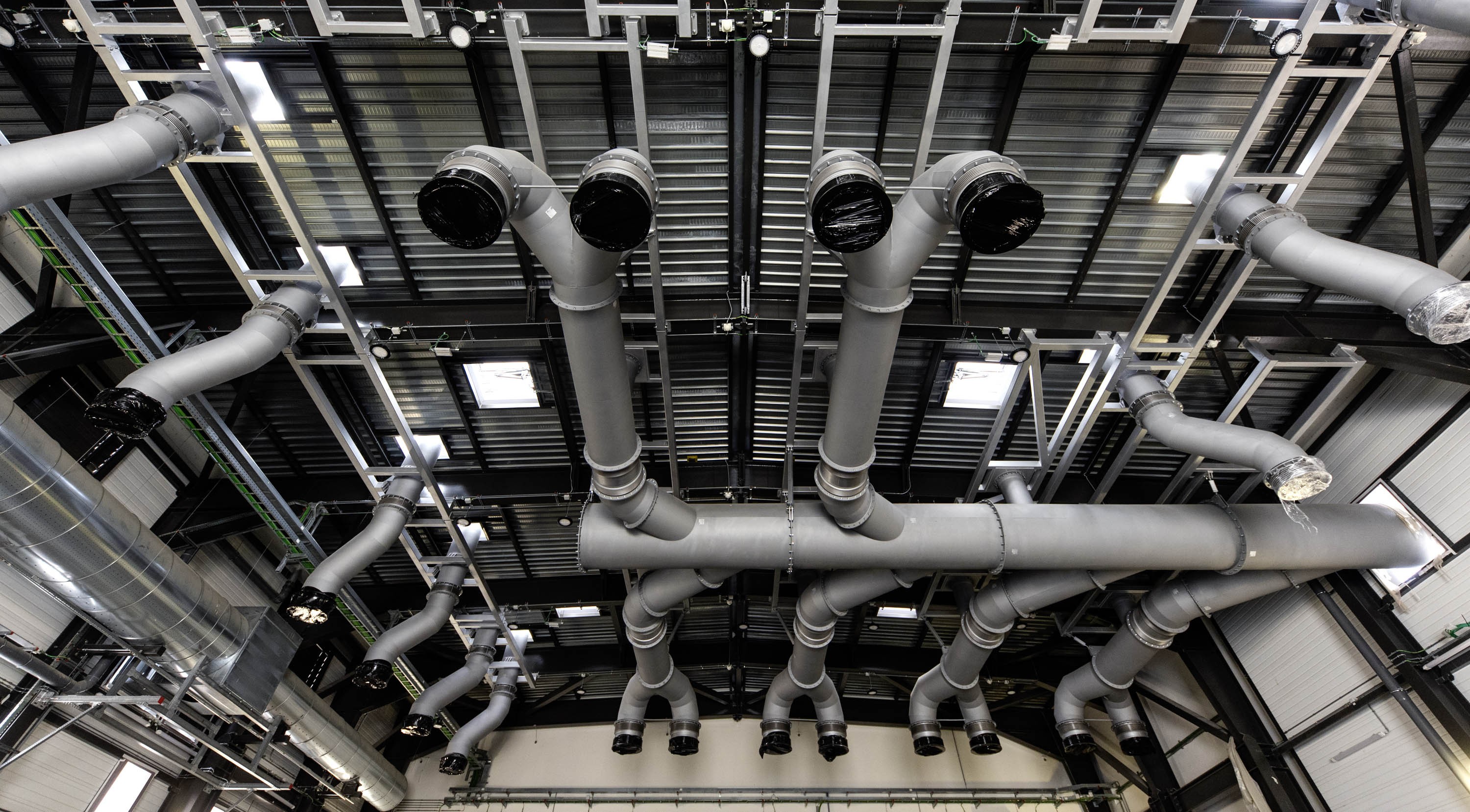

6 — Fast discharge units: In the case of a sudden loss of superconductivity, an event called a quench, a massive quantity of energy (~ 41 GJ), and hence of heat, will need to be extracted from the magnets. This is the role of the fast discharge unit resistors located in these two buildings. The exhaust ducts, connected to a central chimney, are being installed.

7a & 7b — Cocooned cryostat sections: Pending their installation in the Tokamak pit, the ITER cryostat upper cylinder (7a) and top lid (7b) are safely stored outdoors in protective cocoons.

8 — Heat rejection system: The refreshing sound of water cascading down the cooling cells is the newest addition to the everyday noise of the construction site. The heat rejection system is being commissioned in parallel with the cryoplant, whose compressors already generate quite a generous amount of heat that needs to be evacuated.

9 — Control Building: The brain that commands the various facilities spread over the platform occupies a 3,500-square-metre, three-storey structure providing space for control and server rooms, offices, meeting rooms and support facilities. All cubicles (numbering close to 100) are now in place and approximately half of the required connections to the installation's systems have been installed.

10 — Neutral beam power supply installation: Hosted in two buildings, the neutral beam power supply is a unique electrical installation that will accommodate an array of transformers, generators, rectifiers, inverters and other exotic electrical devices designed to feed 1 MeV ultrahigh voltage to the neutral beam plasma heating system. The first 66kV transformers should arrive at the end of the year.

11 — Cryoplant: In order to deliver cooling fluids to the machine, ITER operates one the largest cryoplants in the world. The third and last "train" of megawatt-class helium compressors has recently been turned on. Commissioning of the cryoplant is now 30% complete.

12 — Diagnostics Building: Intense work is underway in the five-storey Diagnostics Building to install the fibre optics needed for the flow of data between instruments near the plasma and the back-end diagnostic systems.

13 — Radiofrequency Building: This building will house the equipment needed by the radio-wave-generating electron cyclotron resonance heating (ECRH) system. Seven and a half years after the start of building construction, control cubicles are being equipped, supports are being built and oil collectors installed to prepare for the installation of the first gyrotrons.

See the gallery below for a few more details on work underway.