Go ahead for vacuum vessel design

The tables in the Salle de la Fenière at the Château de Cadarache were neatly decorated for the wedding party. But the people waiting in the passage next to the restaurant were not waiting for bride or groom ... they were waiting for the wooden wings of the new conference room next door to open. They were keen to listen to the conclusions of the four-day assessment of the ITER vacuum vessel design.

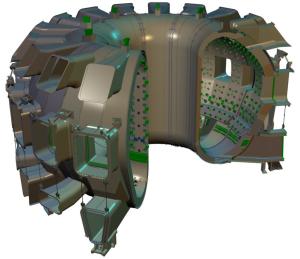

Conducted by Rich Hawryluk, the former Deputy Director of the Princeton Plasma Physics Laboratory, engineers and scientists from around the world together with many ITER staff had investigated the best path forward with the design of the 1,400 m³ steel vessel, the biggest fusion furnace ever built.

The ITER Organization identified in March this year four outstanding issues with the design of the vacuum vessel and its in-vessel components. First, the adequacy of the nuclear shielding of the present vessel with respect to the heating of the toroidal field coils emerged as a concern. Second, it seemed possible that the forces on the blankets through abnormal events could transfer a higher stress than the present allowable to the vessel which is why the design of the flexible cartridges holding the blanket modules and the blanket itself needed to be adapted. Third, the integration of the ELM coils into the present design—especially their connections—was a challenge from the beginning.

The final and perhaps most important issue arose from the feedback received from industries both in Korea and Europe saying that the present design was very difficult to manufacture and in the event of failure, repairs would not be easy to implement. Triggered by these findings and the fact that there was a proposal for an alternative design of the vessel with a self—supporting blanket, the ITER Organization with support from the Domestic Agencies, decided to allow itself a three-month time-out from all ongoing activities related to the vessel design and procurement and to launch a comparative technical assessment on how to best solve the open design issues. A concerted effort coordinated by Guenter Janeschitz.

Last week, it was time to look at the results. "We are discussing a whole gamut of technical issues associated with constructing the critical components," Hawryluk explained in a coffee break on day one of the meeting. "These components have major impacts on other components of the machine and they range all the way from the heating of the toroidal field coils, to the installation and maintenance of the in-vessel coils. So, we are taking a very holistic approach of how to best adopt the necessary changes. We basically ask: What are the technical advantages? Which will meet its technical requirements? Which is easier to manufacture? And which one can be assembled more quickly? So we are going to look at a composite of things. There will be no one single metric that determines the answer to the basic question: Which is the best path forward?"

Four days later, the doors of the conference room opened and the committee presented its conclusions. There was consensus that the alternative approach does hold certain advantages, but that it was not developed far enough to erase the emerging uncertainties. Due to the fact that the reference design is much more mature at this time and with some necessary modifications much closer to meeting the technical requirements of ITER, the committee thus recommend going ahead with the reference design "with the understanding that the design and integration of the in-vessel coils are satisfactorily resolved and confirmatory analysis of the nuclear heat load is completed."

In order to meet these requirements, Guenter Janeschitz summarized what now needs to be done: "The wall of the vacuum vessel will be moved out by 4.5 centimetres to make room for the ELM coils and the manifolds. To provide a better neutron shielding the blankets will become thicker and their steel-water ratio will be changed to 80/20 percent. That will reduce the heating of the toroidal field coils due to neutron heating below 14 kilowatt. Due to changes in the blanket design, the electromagnetic forces during disruptions will be reduced by a factor two and are thus within the limits. Last but not least, following more intensive discussions with the industry, they assured that with some modifications, the reference design can be built."

Nevertheless, the panel in its conclusion pointed out that, "the assessment of the alternative design does have two lasting benefits: In the short run, it encouraged necessary changes to the reference design resulting in an improved baseline. In the longer term, it has developed concepts, which will be beneficial to DEMO."