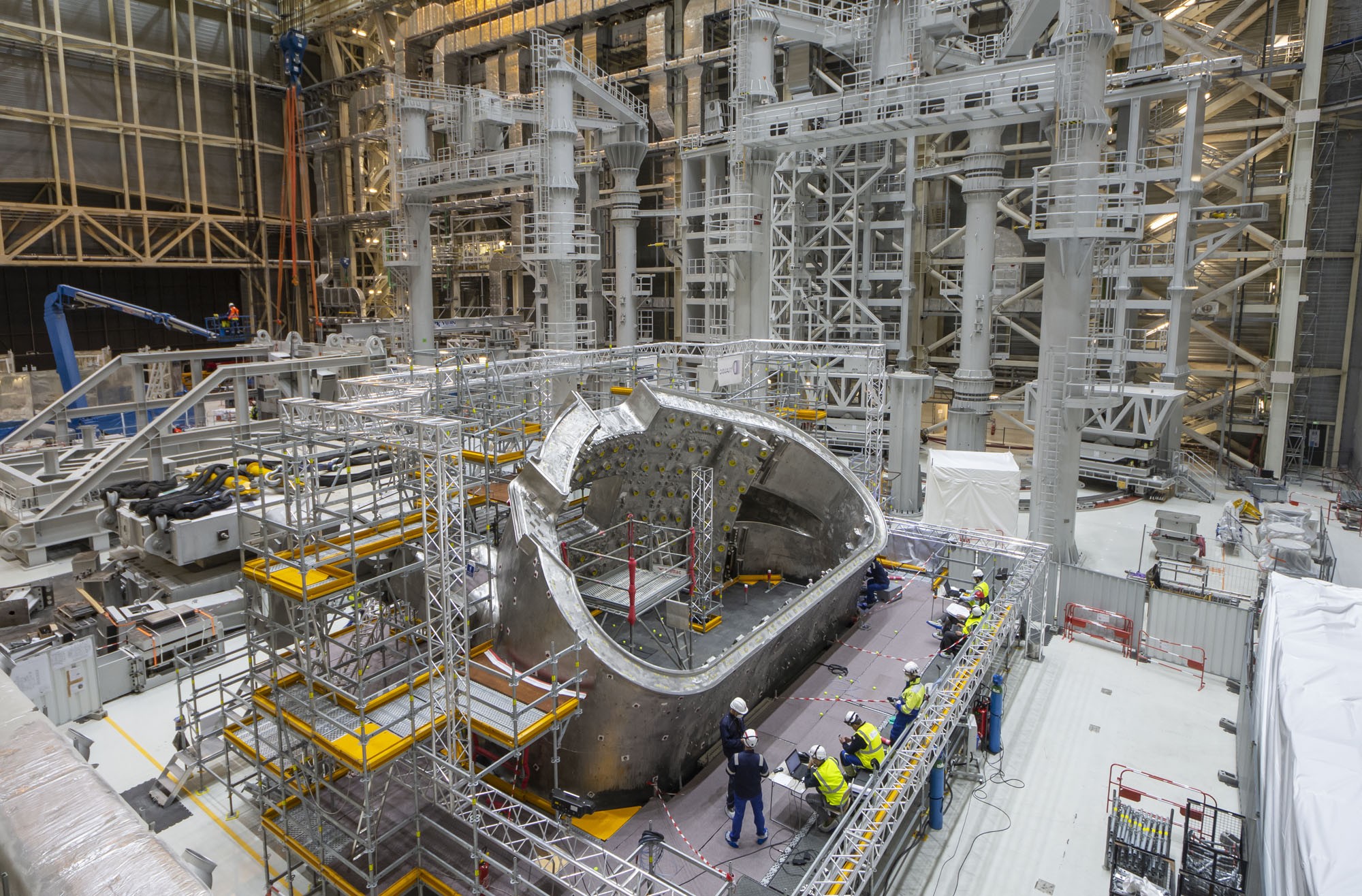

First welding on the vacuum vessel

The number of cylindrical devices (or barnacles if you prefer) is growing by the day: since work began last Wednesday, close to 150 of these objects, called "bosses," have been welded to the component's outer surface and the total should reach over 700 within a few weeks.

Bosses are like studs onto which other components can be bolted or welded to the vacuum vessel. They are designed to support the instrumentation that monitors the main electromagnetic parametres of the plasma—the shape of its boundary along with other data. Bosses are also used to support the cable trays that guide the sensors and instrumentation cables away from the vacuum vessel, along the vacuum vessel wall, through the cryostat, the bioshield, and eventually to the control cubicles and electronics located in the Diagnostic Building.

The precise positioning of the bosses on the curved surface of the vacuum vessel sector is achieved using an innovative technique called "laser templating." Drawing from 3D models of the vacuum vessel and diagnostics, a laser beamer projects the outline of the element to be welded at its precise pre-defined position on the component's surface, providing the welder with a perfect template. It is the first time that laser templating has been implemented on ITER for such an application.

Identical operations will be repeated on the exterior walls of the eight other vacuum vessel sectors prior to pre-assembly. As for the equipment planned on the inner walls, it will be installed once the vacuum vessel pre-assemblies are inside the Tokamak pit. In total, 30,000 welded attachments, fitted to within a few millimetres of tolerance, need to be welded to the vacuum vessel.