China launches series production

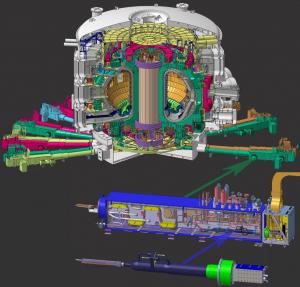

Because they reduce the input power requirement for plant operation, high-temperature superconducting (HTS) current leads are one of the enabling technologies (together with superconducting magnets) for large-scale fusion power plants. First driven by the high-energy physics accelerator community, the development of high-current HTS leads is now being pushed by magnetic confinement fusion towards larger currents. At 68 kA, the ITER toroidal-field type HTS current leads will be the largest ever operated.

- The successful testing of a pair of correction coil 10 kA current lead prototypes in March 2015;

- The successful testing of a pair of toroidal-field type 68 kA current lead prototypes in July 2015;

- The successful testing of a pair of poloidal-field/central-solenoid type current leads in 2016;

- The completion of a Manufacturing Readiness Review in August 2016 (marking the end of the qualification phase).

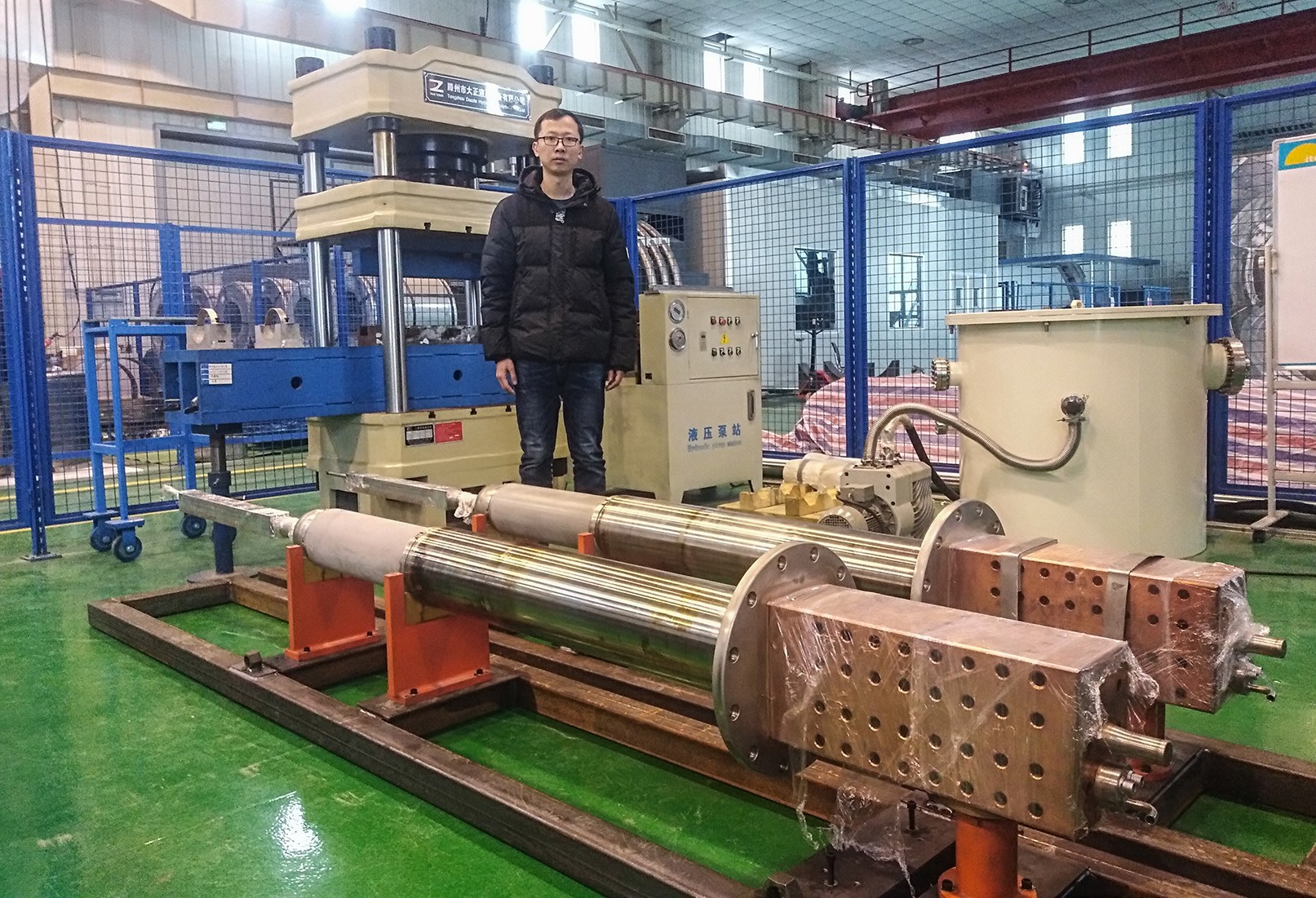

Series manufacturing is now underway, and the first-of-series for all three types of HTS lead have been completed (see gallery). The fact that manufacturing is proceeding strongly, with only a small number of non-conformities, is a tribute to the thorough qualification efforts as well as the Chinese manufacturers' high level of expertise.

It should also be noted that the Chinese Domestic Agency and the ITER Organization put a supervision framework into place allowing local inspectors to witness critical manufacturing steps. Erwu Niu of the ITER China office now manages at least two inspectors who are permanently stationed at the suppliers' sites in Hefei.

Thousands of documents have already been uploaded to the ITER Organization Manufacturing Database—from material certificates, to personnel certificates and test reports. Documents attesting to the components' performance during testing—for example the final factory acceptance cold test in near-to operational conditions under full current—can be fully verified through the database before the final ITER Organization hold point is released.

At ASIPP, lead engineers Quan Han and Qingxiang Ran are now turning their attention to ramping up the pace of production to meet the ITER schedule. A number of additional pieces of large-scale manufacturing equipment—such as another electron-beam welding machine, insulation curing autoclaves and a third cold test station—are being commissioned to handle the extra load.

This year and next, up to 20 current lead pairs will be manufactured in parallel in by Juneng and Keye for shipment to ITER.

¹The qualification of the HTS current leads in China is summarized in an ITER Technical Report (Reference: ITR-18-001). You can download it on this page.