The lower cylinder of the ITER cryostat is but one section of the

giant thermos that will envelop the ITER Tokamak. Standing 12 metres high, it represents one-third of the total height of the ITER machine. As operators stood close to it, carrying out the highly delicate transfer operation, one could measure how tall, large and massive ITER will be.

Transferring the near-500-tonne load from its assembly site to the storage area a few dozen metres away required no less than four self-propelled modular transporters arranged in a square and moving in perfect coordination. Particularly impressive was the sharp 90-degree turn that the trailers had to take in order to reach the storage area—192 independent wheels slowing rotating at different angles, like small appendages of a powerful living organism.

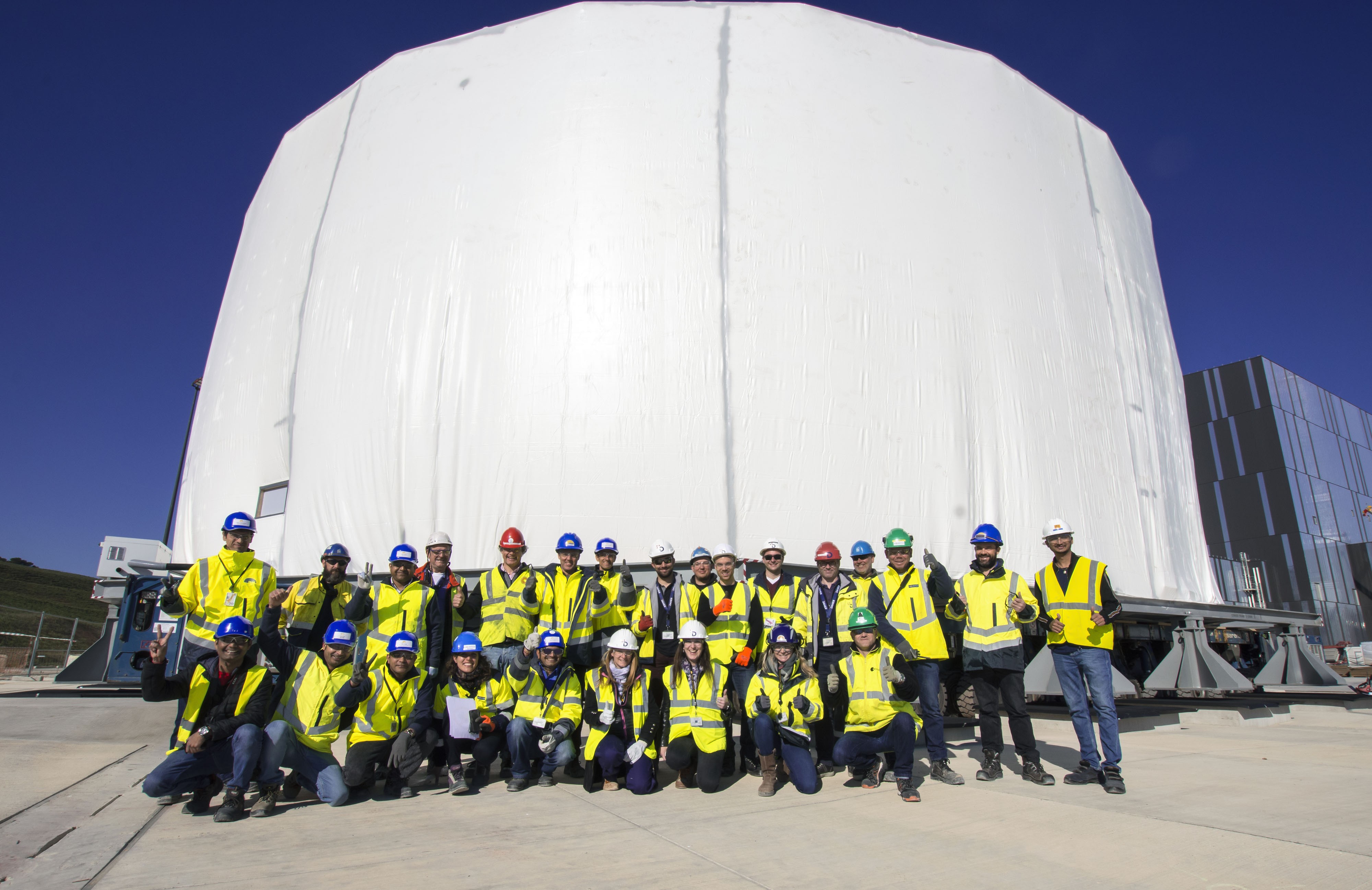

To date, the lower cylinder is the heaviest load to be moved on the ITER platform. Solidly encased in its steel frame and carefully

cocooned in air-tight material, it will remain in storage until the time comes to move it into the assembly pit.

The operation on Monday was a key milestone involving a dozen stakeholders—the cryostat team; heavy load transport specialist Sarens; metrology experts from ITER; global logistics provider DAHER, and many others (see box).

Transferring the lower cylinder to the storage area has freed a large working space inside the Cryostat Workshop. Soon, this space will be occupied by the assembly and welding operations for the upper cylinder whose segments are already on their way from their

manufacturing location in India.