Workers from Nuvia Travaux Spéciaux (NTS) now do it an average of five times a day—a spectacular increase from the ten times per week average of mid-October. Still, although becoming routine, the installation of an anti-seismic bearing remains a delicate operation.

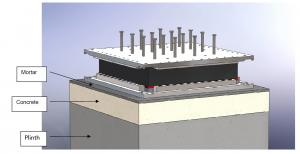

Anti-seismic bearings, which are 18-centimetre-thick sandwiches made of alternate layers of steel plate and rubber, are essential to the seismic safety of the Tokamak Complex . Their function is to filter and mitigate the ground accelerations that a seismic event, should it occur, would generate.

The basemat of the 300,000-tonne Tokamak Complex will rest on 493 of these anti-seismic bearings, arranged in a pattern that optimizes their efficiency. Last Thursday 3 November, a symbolic milestone was reached as the 100th anti-seismic bearing was installed in the northeast corner of the Tokamak Pit.

Before installation begins, NTS, a French company based in Aix-en-Provence, has to accept each plinth. The acceptance procedure consists in checking the surface elevation, its roughness (which guarantees that the second-phase concrete will adhere perfectly), and also in verifying the precise height of the reinforcement at the top of the plinth.