Chinese team completes prototype for ITER's feeder system

18 Jun 2014

-

ASIPP Feeder Team

The Chinese Institute of Plasma Physics (ASIPP) has successfully accomplished a full-scale qualification prototype for one of the key components of ITER's magnet feeder system—the vacuum vessel that will provide thermal insulation to the components at the very end of the feeders inside of the Tokamak gallery.

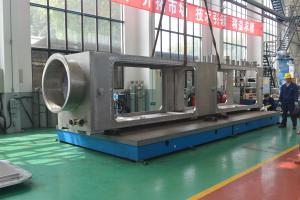

The CTB/SBB vacuum vessel is the largest and heaviest feeder component, with a final, fully loaded weight of 27 tonnes. (Photo courtesy ASIPP)

The ITER superconducting magnet system consists of 18 toroidal field coils, 6 poloidal field coils, a central solenoid (6 modules), 18 correction coils, and finally a coil supporting structure. Leading away from the magnets, 31 superconducting magnet feeders will provide connections to the power supplies, the cryogenic plant, and the magnet control and safety units. Each feeder is made up of an in-cryostat feeder, a cryostat feed-through, and the coil terminal box/S-bend box (CTB/SBB) assembly.

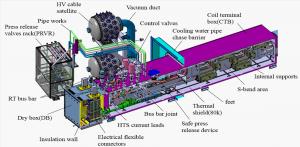

At the end of the feeders, within the Tokamak gallery, are the critical CTB/SBB boxes where electrical power and cryogens are relayed through the warm-cold barrier of the cryostat to ITER's powerful magnets that operate at currents from 10 kA to 68 kA.

The vacuum vessel will provide thermal insulation for the hundreds of encapsulated cryogenic components that are part of the coil terminal box and S-bend boxes. (Photo courtesy ASIPP)

A protective vacuum vessel will provide thermal insulation for hundreds of encapsulated cryogenic components that are part of the boxes such as a 80K thermal shield, high temperature superconducting current leads, superconducting busbars, cryogenic coolant circuits with control/safety valves, cold sensors and signal cables, and cold mechanical supports (see diagram). The CTB/SBB vacuum vessel is thus the largest (8m×1.3m×1.5m) and heaviest (18 t) feeder component. The final weight of a fully loaded CTB/SBB, vacuum vessel included, is 27 tonnes.

In order to meet ITER's stringent quality requirements, the Chinese manufacturer conducted a series of welding trials and assessments and submitted as many as 82 quality documents to the ITER Organization. A number of experts and certified third-party inspectors were invited by the ITER Organization to witness different stages of key welding processes as well as vacuum leak checking, non-destructive testing, and large component measurements.

The successful realization of the full-scale qualification CTB/SBB vacuum vessel prototype is a significant accomplishment within the scope of the Magnet Feeder Procurement Arrangement. The experience gained in this prototype qualification has laid a solid foundation for the high quality series production ahead. The qualified component will now be used at ASIPP to provide the necessary vacuum environment for the downstream cryogenic qualification tests of the 80K thermal shield and the high temperature superconducting current lead prototypes, as well as the full-size mockups of the S-bend busbars with high voltage insulation.