Preserving the view and the vacuum

Punctuating the inner surface of the vacuum vessel are many strategically placed windows that will be used by diagnostic systems to "observe" the plasma.

"The windows are an indispensable component of ITER," says Sunil Pak, Boundary Penetration and Port System Group Leader of the Diagnostic Engineering Section. About half of the ITER diagnostics are optical or microwave diagnostics—systems that operate from a protected location inside a port plug and peer into the plasma through small windows covered by transparent material.

Because these windows are part of the vessel, they must also—in addition to providing transparency for viewing—reproduce some of the critical functions of the wall. They need to be leak proof so that the vacuum in the vessel is preserved, and they must be able to maintain nuclear confinement.

A total of just over one hundred windows are built into diagnostic ports around the vacuum vessel. "We try to standardize as much as possible, so different systems can share a window," explains Pak. "On average, one standardized window is used by three or four diagnostics."

Critical design features

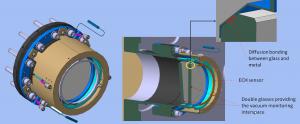

Almost all window assemblies will be based on a double-disc design with an interspace that is monitored. But beyond that common feature, different design attributes will be used to meet the requirements of specific diagnostic or groups of diagnostics. Aperture discs (the transparent part of the assembly) range in size from 25 to 160 millimetres in diameter. The material used depends on the diagnostic frequency ranges—for example, infrared, visible, or ultraviolet all require different materials—and on the expected power load. The choice of materials includes fused silica, quartz, sapphire, zinc selenide, and diamond.

The window assemblies must also be leak free to preserve the vacuum in the plasma chamber and maintain confinement. To monitor for leaks, the service vacuum line is connected to the interspace between the two discs, where it measures pressure continuously during machine operation. To prevent leaks at the seams, bonding or sealing methods are used to tightly join the transparent material to the surrounding metal.

"One technique is to put the stainless steel and the transparent material in a vacuum and then place a thin aluminum layer between them," says Pak. "We raise the temperature up to 500 °C and keep it there for two hours until the aluminum starts to melt. Then we put pressure on the disc and cool it down slowly over a period of one to four hours. This technique, called diffusion bonding, causes the aluminum to diffuse into the glass and metal."

Diffusion bonding requires very good axial symmetry. As the temperature is lowered from 500 °C to room temperature, the metal shrinks more than the glass, compressing the disc along the way. Asymmetry might cause localized compression, which could lead to the formation of defects during ITER's lifetime.

"We have a very high peak stress on the glass due to this small metal seal, so there is a higher chance for a crack," explains Pak. To eliminate that risk, the team performed thermocycling experiments on prototypes—and those tests proved they got it right.

Another challenge is electron cyclotron (ECH) stray heat on the window due to power injections that are not absorbed in the plasma. This stray heat can propagate to the window through optical paths and may cause damage on the disc. To mitigate this risk, the inner surface of the optical path is coated with electromagnetic wave absorption material, a mixture of aluminum oxide (Al2O3) and titanium dioxide (TiO2). Moreover, every window is equipped with a sensor that continuously monitors for ECH stray power.

Maintenance and repair during operations

The diagnostic window design is based on the windows used on the European tokamak JET, but with several modifications to meet ITER requirements. They must demonstrate that they can keep the confinement function in ITER against all the normal and abnormal loading conditions. Furthermore, to ensure the soundness of the windows for the duration of the machine's lifetime, a more rigorous set of inspection and maintenance procedures are required, starting with protocols for both preventive and corrective maintenance.

The windows are designed to last the lifetime of ITER and they also have on-board monitoring. However it is still planned that they be inspected at least once during their lifetime, starting with a check for visible cracks and for any peeling of the antireflective coating. A second helium leak test will be performed by injecting helium in the transparent surfaces to make sure there are no fissures.

The road ahead

Each type of window follows a different timeline for design, manufacturing and testing. The nuclear safety qualification activities for fused silica windows have started and the prototype that will be used for a qualification test is being manufactured. The qualification test will be completed by the end of 2024.

"In the meantime," says Pak, "we are finalizing the design for three other types of windows—zinc selenide for the interferometer diagnostic systems, small aperture windows for the high-field reflectometry system, and CVD diamond windows for the collective Thomson scattering system."

The diagnostic windows provide eyes to observe the plasma—and at the same time, they are safety important components, maintaining the primary torus vacuum and contributing to the safety confinement barrier. The ITER window team is committed to the delivery of high-quality windows meeting those essential requirements.