How to assemble ITER's backbone

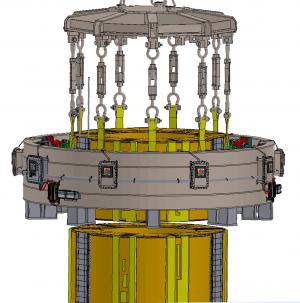

The tools include: an assembly platform where the modules will be stacked; a lifting device to handle the modules and stack them on top of one another with millimetre accuracy; a rotating fixture to turn over the three lower modules; a man-lift to allow performance of operations inside the inner bore of the modules; a drill guide fixture to allow drilling holes in the interface between modules in order to insert shear pins preventing relative displacement between modules; a lead extension alignment fixture, and a lead support structure.

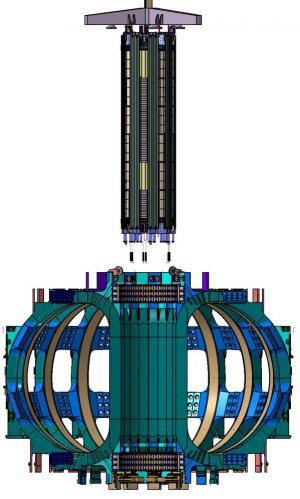

Once installed in the Tokamak, the central solenoid will be supported at its bottom on lower supports attached to the bottom of the toroidal field coils and kept centred at its top by a system of rods attached to the top of the toroidal field coils. The lower supports are thus the first components to be put in place. The central solenoid can then be lifted by the crane and lowered into the Tokamak.