First steps toward commissioning

Every week since the beginning of November, a tube trailer filled with approximately 4,600 cubic metres (750 kg) of compressed gaseous helium delivers its load to the ITER cryoplant. At a later stage, the deliveries will become more massive, as helium is delivered in liquid form in 25,000-cubic-metre (4-tonne) cryogenic containers. Progressively, the helium inventory in the cryoplant will reach the volume required to accommodate the different "clients" inside the tokamak: the lion's share for the superconducting magnets and the cryogenic pumping system, a smaller percentage for the cryostat shielding.

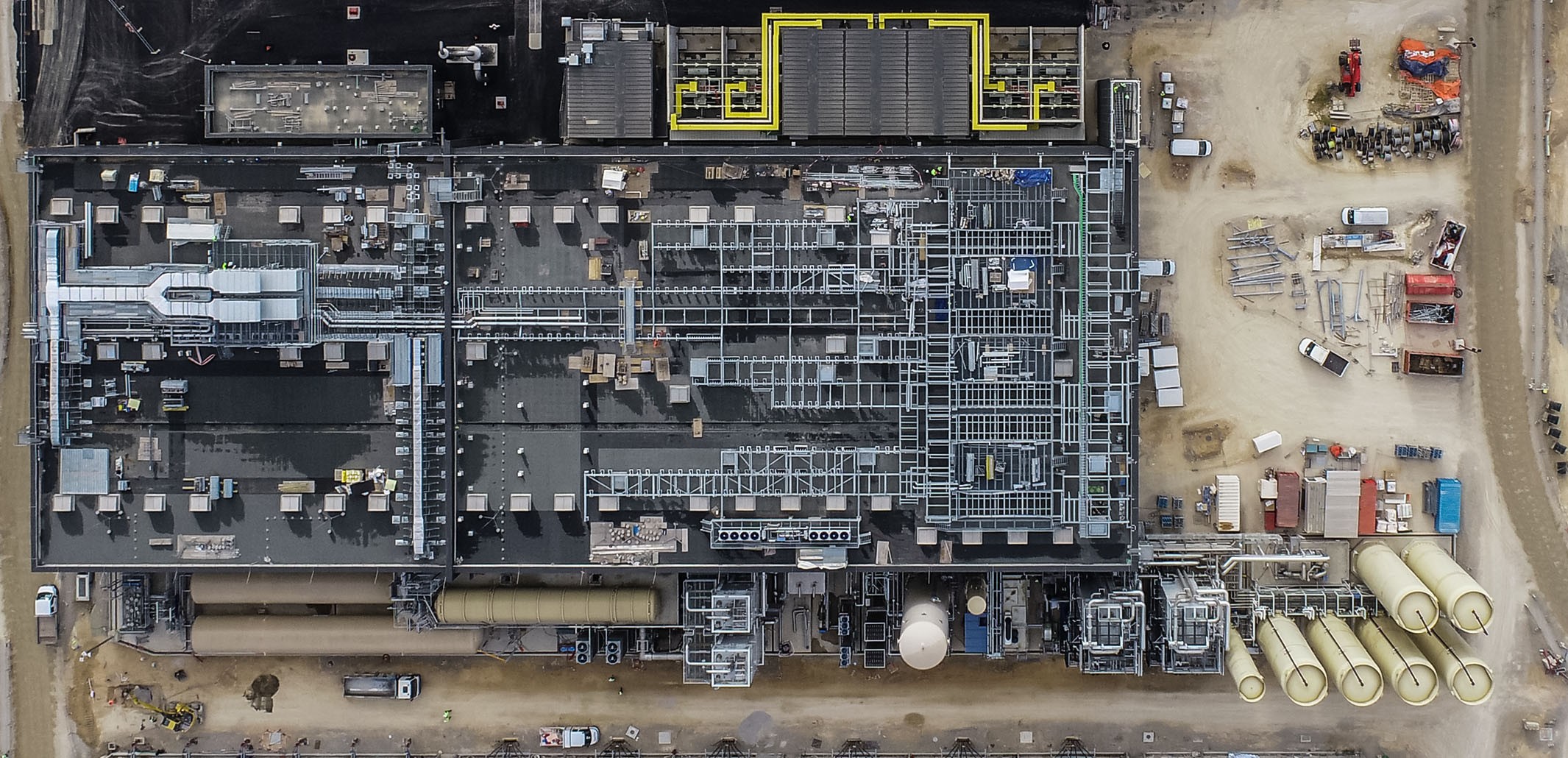

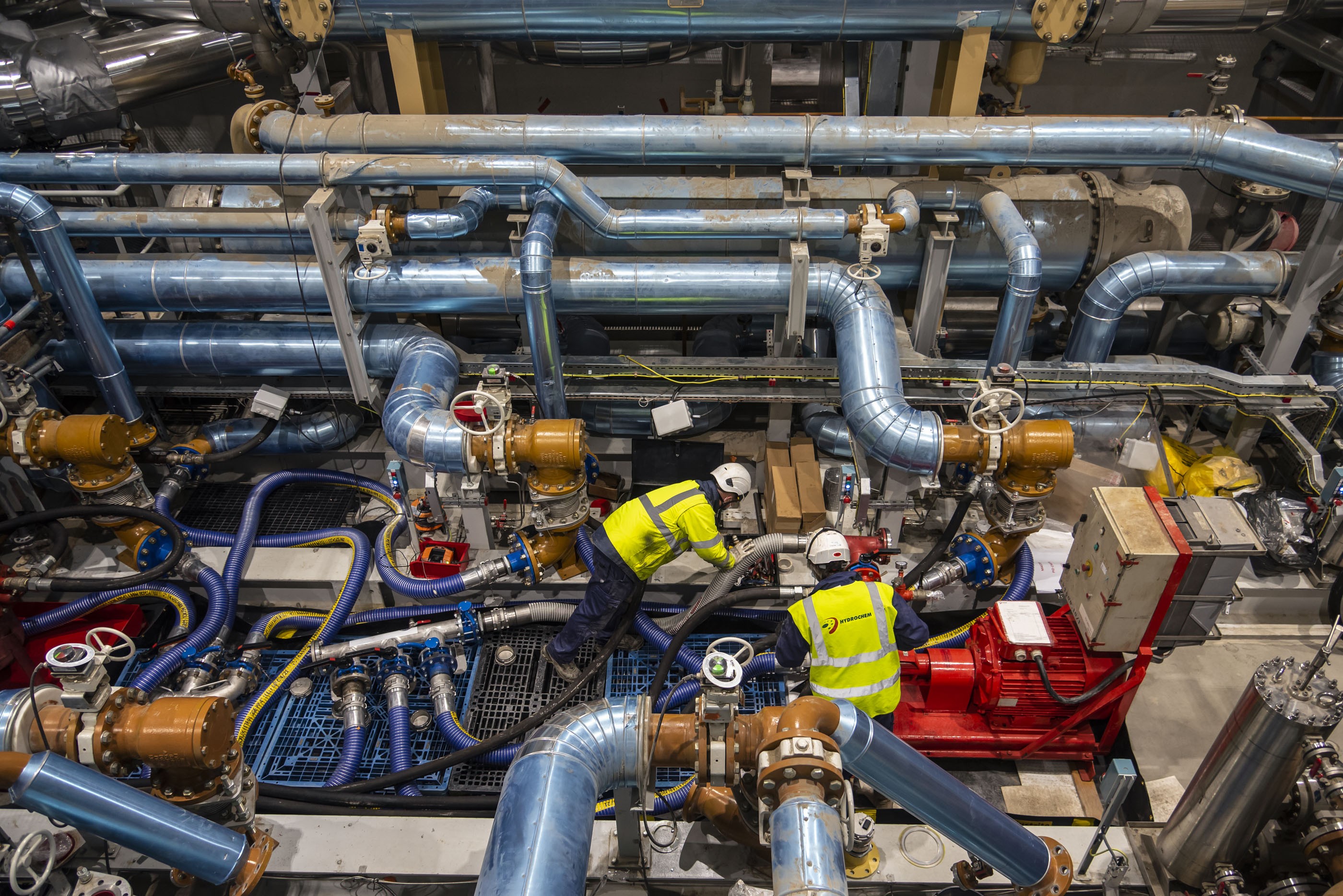

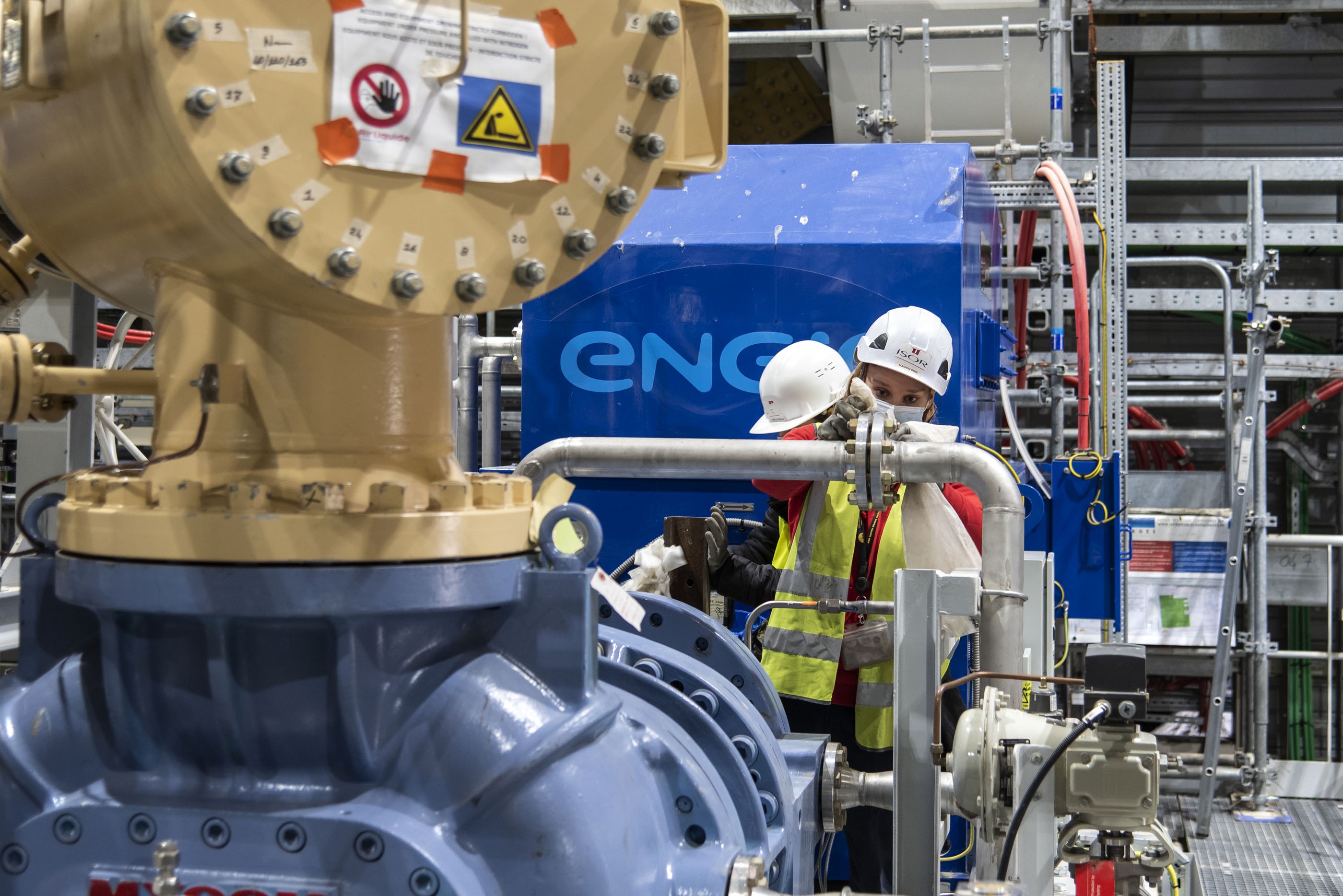

Constituting the helium inventory is a decisive step toward the commissioning of the cryoplant installation. "Over the past three and a half years, we have assembled and installed some 5,000 tonnes of equipment and laid many kilometres of piping—work accomplished through approximately one million work hours and a peak of 200 full-time workers," explains David Grillot, the head of ITER Cryogenic System Section. "We are now entering the pre-commissioning phase which includes testing and verifying control-command systems, performing leak tests, and ensuring cleanliness, helium purity and the safety of the equipment."

Like blood in a living organism, helium is at the core of cryoplant operation and performance. "The helium we receive from the tube trailer is extremely pure—no more than 2 ppm (parts per million) of non-helium molecules. In our processes we must remain below 10 ppm, which means that we must create a vacuum in all our tanks and piping before filling them—what we call the 'helium inerting' process."

Helium is not the only cooling fluid involved in cryoplant operation. In January 2022, special truck trailers will start delivering what will constitute the "first load" of liquid nitrogen (400,000 litres) to be used as a pre-cooler in the helium cooling process. (During operation phase, an air separation unit will extract nitrogen directly from the air to compensate for the inevitable losses.)

The final commissioning sequence of the cryoplant is heavily dependent on the availability of other systems and installations. Compressors, turbines and electrical motors are powerful machines that require considerable cooling power that will only become available when the ITER heat rejection system is fully operational. "Fortunately, a large part of the pre-commissioning can be done without the availability of cooling water," smiles Grillot.

Likewise, the flow of supercritical helium in the Tokamak Building will need to be tested before all magnets are fully installed. As a consequence, "bypasses" will be installed to create a closed circuit and verify that the cryogenic system mission can be properly achieved.

Operational acceptance testing will begin in the first months of 2022. "If everything goes well, the cryoplant will be in marching order in 2024," says Grillot. For the head of the ITER Cryogenic System Section, the adventure will have lasted more than ten years—first as the engineer in charge of design and manufacturing at the French supplier Air Liquide, then at ITER since early 2016.

But as always, success will be the result of team work. In the case of the cryoplant, the Cryogenic Integrated Team brings together the three parties sharing responsibility for the procurement of the cryoplant—the ITER Organization, responsible for the liquid helium plant; Europe, in charge of the liquid nitrogen plant and auxiliary systems; and India, whose contractors are procuring the cryolines, the warm lines and cryodistribution components.