Anticipation and flexibility

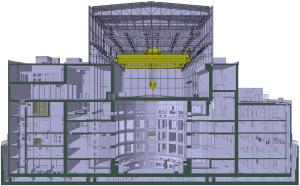

It is a subterranean world of scaffolding and supports, piping and cables, concrete and embedded plates. To the untrained eye, the activity underway in the basement of the Tokamak Complex can seem overwhelming. But everything is being carried out according to a master plan.

The majority of the work has taken place at levels B2 and B2M ("M" for mezzanine) of the Tokamak and Diagnostics buildings. (In the Tritium Building, the bulk of activity is deferred until after the project reaches its First Plasma milestone.) Some 100 workers* are installing cryolines, cooling water lines, cable trays, heating/ventilation/air conditioning (HVAC) equipment, and scaffolding, and making sure all materials required for future installation tasks are available.

The installation sequences have been carefully planned. Beginning in the lowest (B2) level of the Tokamak and Diagnostics buildings, contractors are progressing room by room in a counter clockwise manner around the Tokamak pit before moving to the next level (B1). Step by step, task by task, the teams are installing and connecting the systems and equipment needed to feed the machine, with a peak of activity expected in 2022 and 2023.

The Tokamak Complex Process Installation Section faces two major challenges. The first is determining the allocation of space and the installation sequences to follow in order to achieve maximum efficiency—in other words which elements to install where and in what order. The routing of components through the building, and between or through other pre-positioned or installed components such as cryolines and busbars that cannot be modified, is complex and must be carefully considered to avoid potential conflicts.

Systems installation is carried out according to a strict plan. The supports go in first, and then typically the HVAC equipment and cable trays are installed near the ceiling. What absolutely must be avoided is installing something and then later having to take it out. In the planning, the teams are constantly superimposing two different pictures—what the room or gallery looks like today, and what it must look like once the construction is over. Taking into account the path of irremovable busbars and cryolines, supports and systems need to be installed at a precise location and welded to embedded plates that have been validated to support the associated load.

Anticipating the purpose of each penetration

The second challenge is dealing with the 4,600 "penetrations" (or openings) that provide passage for pipes, cables, diagnostics and HVAC between buildings and rooms. In the Tokamak Complex, many are located in crucial areas such as the 1.5-metre-wide outer walls of the Tokamak Building and the 3-metre-wide inner walls surrounding the Tokamak pit that must be filled in for nuclear shielding.

The team needs to know exactly what kind of system will be installed inside and on either side of a penetration to design and fill it properly. "First, you reduce the large openings with concrete backfilling, designed with specific cut-outs for cables, for example, pull them through, then seal the gaps with infilling materials to restore the wall and give it back all its properties in terms of fire protection and sectorization, confinement and radiation shielding," explains Benjamin Moellinger, coating and corrosion engineer. "You can't move along with the build and put your systems through until you get the penetration designed and backfilled."

Cryolines, busbars and penetrations are brought into the equation to design the most efficient sequences for the installation of all systems. Still, no matter how much the teams anticipate, they sometimes need to adapt last minute. As a first-of-a-kind project, plenty of adjustments are anticipated throughout the whole build. The Process Installation Section has the processes in place to identify and solve unexpected difficulties in the most efficient manner, always with an eye to not delaying the schedule.

For more on plant assembly see these pages of the ITER website.

* The Construction Management Office and ITER's Construction Management-as-Agent (CMA), MOMENTUM, coordinate the day-to-day work on the construction platform. For the Tokamak Complex, work has been broken down into three major contracts: TCC0 (early works, now active) and TCC1 and TCC2.