A very international effort

Like the vacuum vessel sectors, the ports are Safety Important Class components whose manufacturing requires strict quality assurance and close adherence to the nuclear code and regulations. Compliance to safety requirements at all fabrication stages is controlled by the Agreed Notified Body¹ (ANB Vinçotte, Belgium).

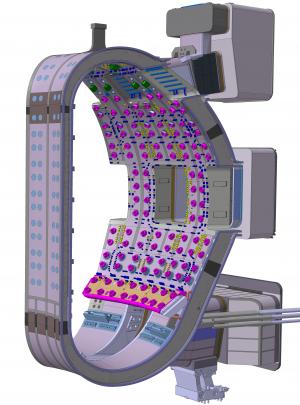

The ports will be manufactured and installed in two phases—the 3- to 7-metre-long port stub extensions will be shipped to sector manufacturers and welded directly onto the vacuum vessel sectors, while the second-phase port extensions will be delivered directly to the ITER site and installed after the magnets in the Tokamak assembly pit.

In Russia, the procurement of the 18 upper ports has been underway under the responsibility of main contractor NIIEFA (the Efremov Institute) since the signature of the Procurement Arrangement in 2009. NIIEFA has extensive experience in ITER standards and requirements, having led and coordinated R&D work undertaken by Russian laboratories for the modelling of high-vacuum and high-pressure components, in-vessel plasma-facing components, and the ITER divertor.

In advance of or in parallel to the manufacturing activities, which were launched in 2014, ITER Russia has developed quality assurance documents and had them agreed by the ITER Organization, completed drawings, procured material (over 1,000 tonnes of austenite steel procured in Europe), selected the primary manufacturing contractor (2012), certified welding procedures, and qualified welding and non-destructive testing personnel in accordance with French nuclear regulations. For the fabrication of upper port stub extension #12, more than 250 procedures/documents were prepared by the Russian Domestic Agency and its suppliers.

And there is more: at the completion of each component, factory acceptance tests are carried out by MAN Energy Solutions, with ITER Russia and ITER Organization observers, followed by site acceptance tests in Korea and Europe.

"Being part of the worldwide team to realize ITER has been a challenge as well as an opportunity," says Thomas Schiller, head of Energy & Physics at MAN Energy Solutions. "Engineering and manufacturing such a safety-important component, given the quality and the quantity demanded, has opened a new chapter for MAN ES Deggendorf."

¹An Agreed Notified Body (ANB) is a private company authorized by the French Nuclear Regulator ASN to assess the conformity of components in the pressure equipment category (ESPN).