At Indian Domestic Agency contractors Air Liquide (France) and INOXCVA (India), fabrication is approximately 50 percent complete. Newsline recently visited the Indian facility located in the outskirts of Vadodara, an industrial city with a population of more than two million in the western state of Gujarat (see gallery below).

INOXCVA is a company with a quarter-century of experience in cryogenics, and whose Cryo Scientific Division is deeply involved in space applications, the nuclear industry, and all other major technologies involving cryogenics.

The manufacturing of spools—the 2- to 10-metre sections of cryoline that, once assembled at the ITER site, will form the cryoline network—began in 2017 in a specially constructed workshop complete with a clean room devoted to the most delicate and sensitive operations.

For the team at INOX, the challenge in filling the ITER order lay in the stringency of the technical specifications as well as in the quantity of spools to be produced—approximately 700 of them, each with a different shape.

"The ITER cryolines are all angles, bends and turns. Less than 20 percent of the spools we need to produce are straight," says Sanjay Gajera, the quality responsible officer at the INOXCVA facility in Vadodara.

In the large open space of the workshop, dozens of spools are in various stages of fabrication and, indeed, very few are straight. The factory receives the raw pipes from India and Europe (mainly the Ukraine); once cut to the required dimensions and cleaned, the welding process, which is exclusively manual, can begin. "Because of the complex shapes involved it is impossible to use automatic (orbital) welding machines," says Sanjay.

The inner pipes pass through the clean room to be wrapped in insulating tape multilayer insulation before being inserted into their outer jacket. At each stage of fabrication, the pipes are visually inspected and their internal surface and welds are explored by way of "boroscopy" (using a visualizing tool similar to an endoscope), X-rayed and cold tested.

At the end of this process, the spools are sealed at both ends under a slightly pressurized atmosphere of nitrogen to protect them from corrosion and impurities during storage and transport, and until they are assembled and welded on site at ITER by INOXCVA personnel.

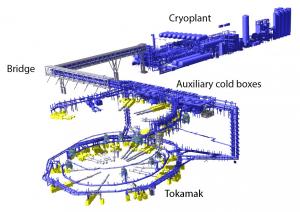

The first batches of INOXCVA cryoline spools reached ITER in July 2017 after a one-month sea voyage from India. Installation in the cryoplant is underway; in the Tokamak Building work will begin this summer. The bridge between the two buildings will be in place in 2023, and the cooling fluids should begin circulating in the crydistribution network in 2024 in anticipation of First Plasma scheduled the following year.

Click here to view a video of the fabrication process at INOXCVA.