Crane versus barge: a tale of Russian ingenuity

26 Sep 2016

-

L.C.

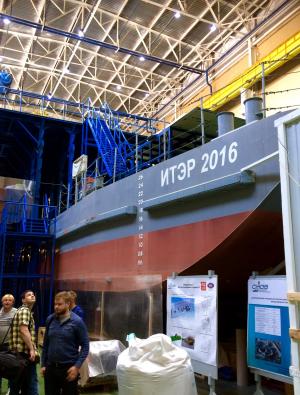

Re-christened ИТЭР 2016, or ITER 2016, a humble barge has become part of the engineering sophistication that is the ITER Project.

The Srednenevsky facility layout is favourable to manufacturing ultra-large components for later shipment. Situated on the Neva River near St Petersburg, the shipyard enjoys direct access to the Baltic Sea and global shipping routes.

Still, when manufacturing a component as large as ITER's poloidal field coil #1 (PF1)—200-tonnes when completed—there remains a not-insignificant engineering challenge: how to transfer this massive component from the construction hall to the transport ship. An obvious solution—but highly expensive—would be to construct a giant crane for this purpose.

The Srednenevsky team came up with a more creative strategy. Most of the multi-stage assembly platform for the PF1 coil fabrication process has been erected atop a stationary barge. This includes the vacuum pressure impregnation of each of the "double pancake" sections with epoxy resin, as well as the assembly of the double pancakes into the finished coil.

When the PF1 coil is complete, it will be lowered to a 45-degree angle for stability. The barge will then be tugged backward out of the construction hall and into the Neva River. There the coil and its platform will be transferred to a ship to begin their long journey "homeward."

Thus a humble barge—aptly re-christened ИТЭР 2016, or ITER 2016—has become part of the engineering sophistication that is the ITER Project.