A strong contribution to neutral beam development

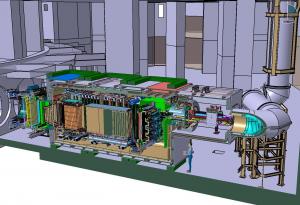

The diagnostic neutral beam—one of ITER Tokamak's three neutral beams—is about to enjoy some time in the spotlight. Work begun in 2009 on the civil construction works of the Indian Test Facility in Ahmedabad is now completed: here, the Indian Domestic Agency will install a full-scale test bed for the qualification of all diagnostic neutral beam parameters before installation and operation in ITER.

"A similar need for research and development applies to the diagnostic neutral beam, however a test facility with DNB-specific objectives was not available," explains Arun Chakraborty, leader and project manager for the diagnostic neutral beam at the Indian Domestic Agency, which is responsible for procurement. "ITER India assessed the need and agreed, in consultation with the ITER Organization, to the configuration of a facility for the full characterization of the diagnostic neutral beam."

"This additional effort and additional resources allocated to the diagnostic neutral beam by ITER India are greatly appreciated," says Beatrix Schunke, senior technical officer at the ITER Organization and responsible on the ITER side for the diagnostic neutral beam. "The specifications for the diagnostic neutral beam are highly demanding. The Indian Test Facility is a voluntary contribution that shows a great commitment to the success of the ITER diagnostic neutral beam program."