On site

As ITER begins assembly, HVAC becomes mission critical

21 Sep 2020

-

Pat Brans

Not only will heating, ventilation and air conditioning (HVAC) help protect people and equipment during the assembly phase at ITER, but they will also help ensure cleanliness in preparation for First Plasma.

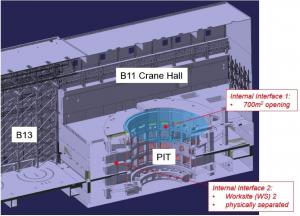

In Worksite 1—which includes the Assembly Building, the crane hall, and the Tokamak pit—the HVAC systems must maintain homogenous temperatures. A change of just a few degrees could introduce minute changes in component dimensions that would make assembly difficult.

The ITER Organization will contract for two temporary and independent HVAC systems that will be installed to support the assembly phase at ITER. One of the HVAC systems will serve Worksite 1, which includes the Assembly Building, the crane hall, and the Tokamak pit. The other will serve Worksite 2, also known as the Tokamak Complex, which includes the Tokamak, Diagnostic and Tritium buildings.

Ensuring temperature, humidity and cleanliness

"At Worksite 1, we have to maintain the temperature, humidity and cleanliness to support machine construction," says Giovanni Di Giuseppe, Section Leader of the Supply & Service Installation Section. "This means maintaining a temperature of 20 °C +/- 2 °C in the winter, and 25 °C +/- 2 °C in the summer. Humidity has to be kept below 70 percent, and cleanliness has to conform to ISO 9 [code 14661] requirements."

One of the goals is to maintain homogenous temperatures between the Assembly Hall—where a powerful HVAC system is already functioning—and the crane hall and the Tokamak pit. A change of a few degrees could introduce minute changes in component dimensions that would make it difficult to fit components together during assembly. Maintaining a constant temperature involves heating and air conditioning, but it also involves ventilation to remove the heat generated by workers and by welds.

More than twenty "hot points," or welding stations, will be situated in the Tokamak pit. Not only do the welds produce heat that needs to be removed, but they also produce argon which, if left in the pit, would pose a double threat: argon causes anoxia and it triggers fire.

"To extract the fumes resulting from the welding we will use specialized equipment, including mobile source capture systems," says Di Giuseppe. "We need to locate the equipment in the crane hall in order to route the ducts inside the pit."

Labels identify discrete working volumes in the Tokamak Complex and pit area. Empty, they are relatively easy to ventilate. But as these areas get filled with components, pockets of air can be created.

French labour code requires a ventilation system that provides 60 m³ of air per hour per worker. None of that air is recycled, so the ventilation system will have to include both supply ducts and exhaust ducts. The ventilation system will accommodate up to 140 workers, which is the maximum number of people allowed in the Tokamak pit at the same time.

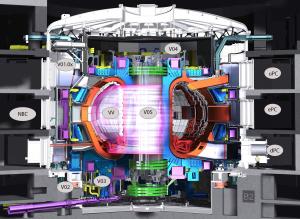

One source of complexity, especially in the Tokamak pit, is that as the machine is constructed, dead zones arise. These areas start out as big, relatively empty volumes that are easy to ventilate, but gradually they get filled with components—and these components create pockets of trapped air.

"Worksite 2 will be a little easier," says Di Giuseppe. "There are no specific temperature or humidity requirements for equipment; however, we do need to maintain conditions that conform with French labour law. There will also be specific activities we will have to support with air locks (isolated rooms where temperature and cleanliness control is required). These activities include cryoline installation, vacuum installation, and Tokamak cooling water system installation. The air locks have to be interfaced to the local ventilation system."

"For the rest of the work areas, we need to condition the environment for worker safety, knowing that as many as 180 people may be on three of the building levels at any given time," says Di Giuseppe. "We will put sensors in place to read pollution levels at both worksites. A special team will go on site periodically to read the measurements and check that the pollution is within ISO 9 levels."

Beyond worker safety and equipment protection, HVAC will support ITER efforts to maintain cleanliness, especially in the Assembly Hall. Ventilation will help keep dust and sub-microscopic particles off components that will ultimately wind up in the vacuum vessel. Any contaminants left on such components could reduce fusion output.

"During the year 2019, we ran a feasibility study for the temporary ventilation requirements," says Di Giuseppe. "We identified the needs, and laid out the main features of how we will implement the temporary ventilation systems. We would like to award the contracts in the fall and start work by the beginning of next year."