DivSOL wagon rolls EAST

With the EAST tokamak in the middle of an extended maintenance period—during which the ASIPP team in Hefei, China will take the audacious step of installing an ITER-like, full tungsten divertor in the upper part of the vacuum vessel by the end of this year (see box below)—what better place to hold the latest in the series of regular meetings of the International Tokamak Physics Activity (ITPA) Topical Group on Divertor and Scrape-Off Layer physics. Known in ITPA circles as the DivSOL TG, this group focuses on issues of importance to ITER in the area of heat and particle exhaust from the tokamak plasma and the unavoidable plasma-surface interactions which occur at the plasma-materials boundary.

Plasma and materials physicists work together within DivSOL to address a host of questions, from movement of material by the plasma and tritium trapping in surfaces, to turbulent transport of heat in the plasma boundary and plasma-facing component lifetime under intense heat fluxes. In common with all ITPA groups, DivSOL is reactive to urgent ITER physics R&D issues and works to find answers to specific requests.

One such example is the flurry of activity stimulated by the ITER Organization proposal in autumn 2011 to eliminate one of the two divertors planned for the first years of ITER operation, up to achievement of burning plasmas. The idea is to go the whole way with a single unit in which tungsten (chemical symbol W) would be the only material intercepting the majority of the tokamak heat exhaust. A single divertor would be a major cost saving to the project, but it is a calculated risk: W is a harder material to work with from the plasma point of view than the carbon fibre composite in originally planned first divertor.

Finding out just how much of a risk, and making sure that a workable design with qualified technology can be ready in time for procurement which must begin next year, was the task set by the ITER Council to the ITER Organization, with a reporting deadline near the end of 2013. All the ITPA groups are lending a helping hand by trying to assess the physics risks of "beginning full-W." DivSOL has a major role to play given that most, but by no means all, of the issues concern the plasma-materials interface.

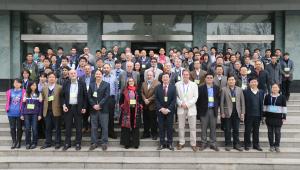

Not surprisingly, living with tungsten was a major theme in the 18th DivSOL meeting, hosted by ASIPP from 19-22 March. It was also a record breaking meeting that reunited over 90 representatives from the ITER Members, including about 50 Chinese participants representing universities and technology institutes from all over China. Such high attendance reflects the importance of plasma-materials interaction not just to ITER, but to the long-term future of fusion as a viable energy source. The meeting was also a good example of the less visible, but essential, role which ITPA fulfills in addition to supporting ITER as a vehicle through which newcomers can take part in lively discussions and presentations, in a workshop atmosphere, with experts from across the ITER Members.

The success of any workshop or conference depends to a large part on organization. Our Chinese hosts led by Houyang Guo of ASIPP (and ITPA DivSOL co-chair), provided a seamless environment for the first DivSOL meeting ever to be held at the Institute. The next DivSol TG will be held in Japan in January 2014.