The ITER central solenoid is the

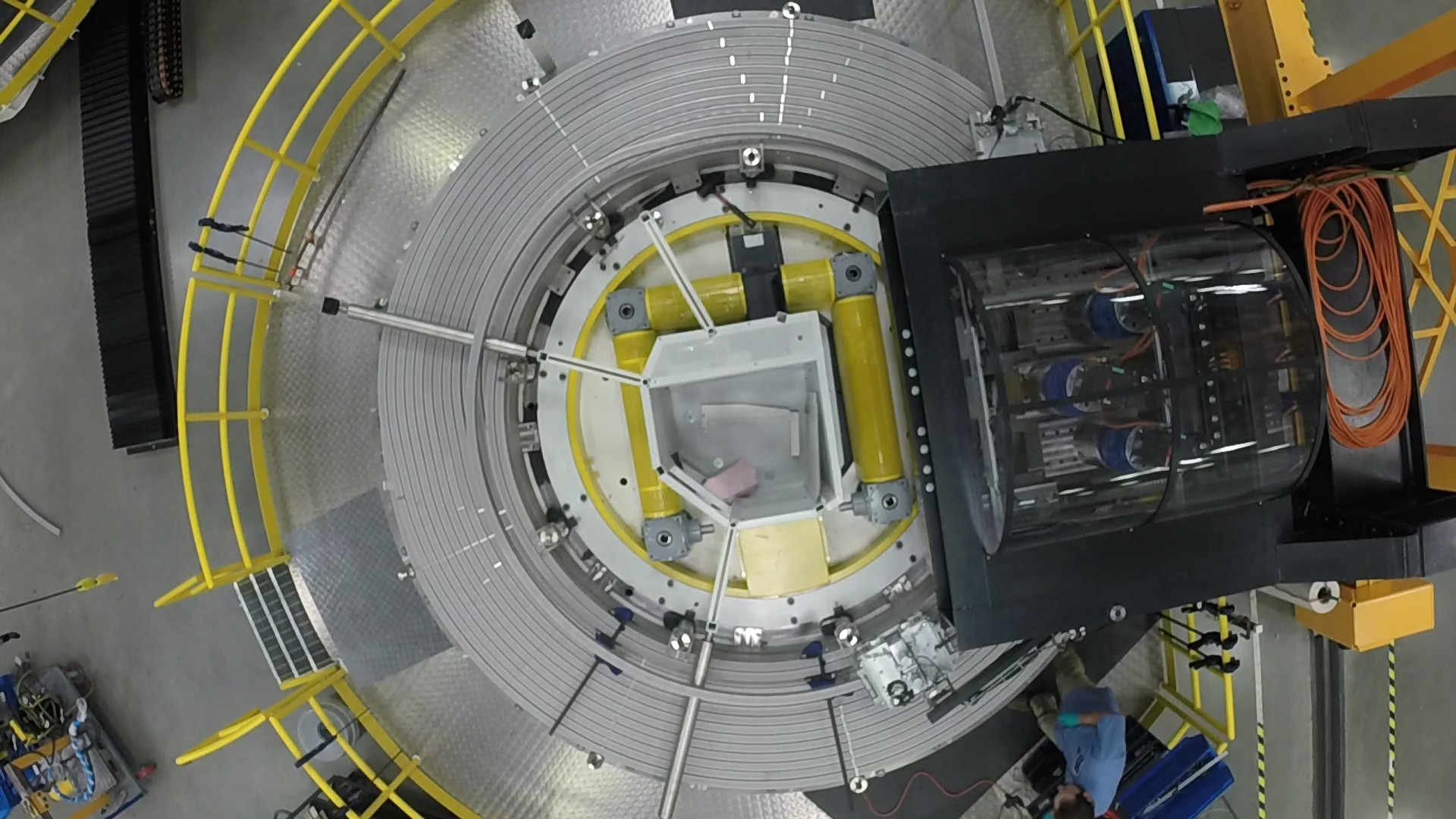

giant electromagnet at the centre of the ITER machine that will generate most of the magnetic flux charge of the plasma, initiating the initial plasma current and contributing to its maintenance. Six individual coil modules will be stacked vertically within a "cage" of supporting structures. General Atomics will also produce a seventh module as a spare.

As part of its in-kind contributions to ITER, the US is responsible for 100 percent of the central solenoid magnet, including design, R&D, module fabrication from conductor supplied by Japan, associated structure, assembly tooling, bus extensions, and cooling connections.

In the photo gallery below, follow the mock coil through the manufacturing workstations, and view the latest pictures of module 1 winding and magnet structure fabrication.

All photos courtesy of General Atomics unless otherwise indicated.