Russia delivers a full-scale prototype

Arranged in a circle at the bottom of the vacuum vessel, the divertor is made up of 54 "cassette assemblies"—each one formed from an actively cooled structural backbone (the cassette body) in austenitic steel and copper alloy, plasma-facing elements covered in tungsten tiles and, for some cassettes, diagnostic systems. The vertical targets directly intercept the magnetic field lines and are designed to withstand heat fluxes as high as 20 MW/m²; the dome, located between the two divertor channels, may face heat fluxes up to 10 MW/m².

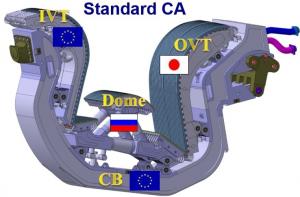

The dome prototype arrived at ITER in December 2021. The next qualification step will be to create the first divertor assembly by integrating the dome prototype and prototypes of the inner (European Domestic Agency, Fusion for Energy) and outer vertical targets (ITER Japan) onto a full-scale prototype of the divertor cassette body (Fusion for Energy).