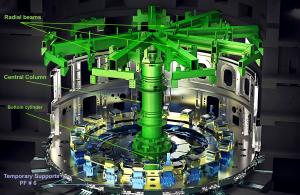

A first glimpse at the colossus

As for the radial beams, they will arrive in the pit supporting each vertical vacuum vessel sub-assembly as it travels by overhead crane. Once installed, the beams (and their loads) are supported between the central column and the concrete bioshield.

In addition to its weight-bearing role, the colossus at the centre of the pit will provide a physical manifestation of the machine axis, prior to the welding of the pre-assemblies. Equipped with a number of fiducial targets, the central column will allow for the ultra-precise positioning and alignment of the toroidal field coils. Fiducial targets on the radial beams will fulfil the same role for the vacuum vessel sectors.