Cryostat

A true sense of size

16 Oct 2017

-

R.A.

Just like a thermos provides the insulation to keep your coffee warm—or your water cold—the ITER cryostat raises a barrier around the superconducting magnets that limits the possibility of heat exchange with the outside environment.

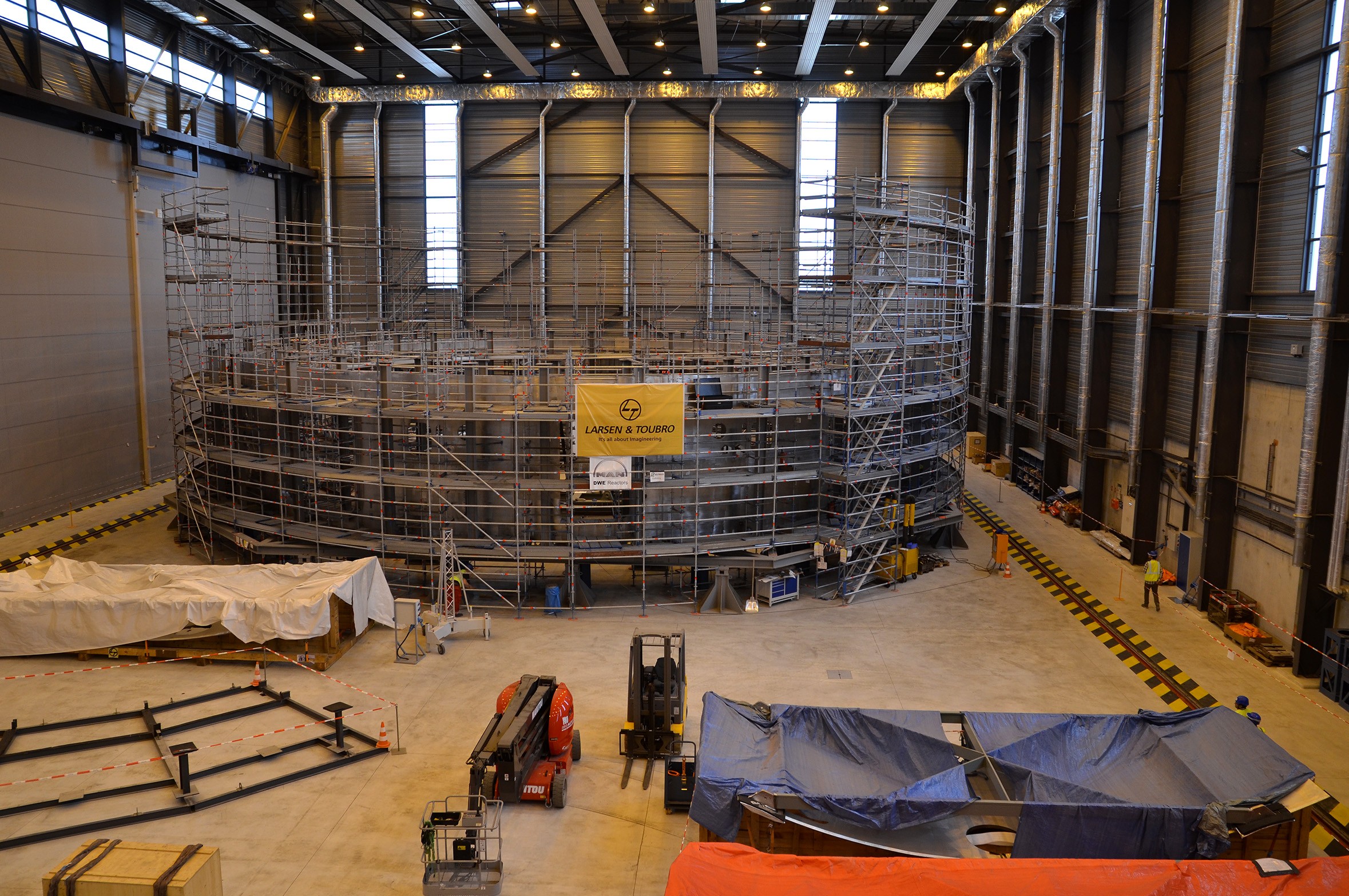

In the Cryostat Workshop on site, two sections of the cryostat are now in assembly in tandem. Here, the team stands inside the ring of the lower cylinder, tier one (30 metres in diameter). An initial pass of the welding tools has all segments now joined; the second tier segments—en route now from India—will top the first, creating a 10-metre-high structure.

Where coffee is concerned, the temperature gradient is small—even on a cold day, the beverage inside the thermos is only a few dozen degrees hotter (or colder) than the air outside. In ITER, the gradient is huge: with superconducting magnets cooled to a few degrees above absolute zero, the difference with the outside environment is in the range of 270 degrees Celsius.

Vacuum (an almost perfect insulator) is used in both a thermos and the ITER cryostat to provide insulation. In the first case, vacuum is sandwiched between the two "walls" of the container; in the second, the vessel itself—a ten-storey structure with a volume of 8,500 m³—is the vacuum chamber.

Part of the procurement responsibilities of India, the cryostat is being manufactured in 54 segments by Indian contractor Larsen & Toubro and shipped to the ITER Cryostat Workshop for assembly.

Over the past year and a half, we have seen the cryostat base take shape; now, work is underway simultaneously on the next section—the lower cylinder. Side by side, these components-in-progress give a true sense of the awesome size of the cryostat.

More on cryostat manufacturing here.