Testing plasma-facing components in St Petersburg

12 Nov 2012

-

Alexander Petrov, ITER Russia

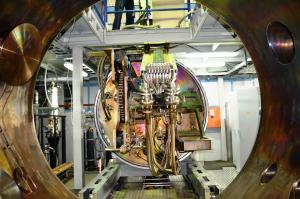

A 800 kW electron injector exposes the components to the same heat loads - up to 20 MW/m2 - they will face inside the ITER vacuum vessel.

The first testing of plasma-facing components for ITER's outer divertor target full-scale prototype started at the Efremov Institute in St Petersburg, Russia in late October.

These crucially important and sophisticated heat-capturing elements will be in direct contact with the plasma—a first barrier that will withstand the main heat flux from plasma during operation. As the plasma temperature is to reach 100-150 million °C, and the expected heat load on the divertor surface up to 20 MW/m2, the components under test have challenging requirements to meet.

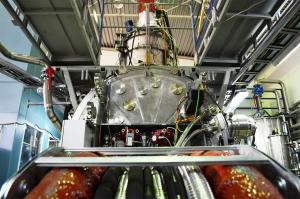

To conduct the tests in Russia, a special ITER Divertor Test Facility was assembled at the Efremov Institute as part of the Russian commitment for the ITER Project. Within the Facility, an 800 kW electron injector exposes the components to the same heat loads they will face inside the ITER vacuum vessel in the standard operational mode and allows the testing of their reliability.

The tests being carried out in Russia's northern capital are a vivid example of close international cooperation within the implementation of the ITER Project: the components were manufactured in Japan and shipped by our Japanese colleagues directly to St Petersburg for testing at the Russian facility. In compliance with the spirit of tight international collaboration, the works are being carried out in the presence of Russian and Japanese Domestic Agency specialists, as well as experts from the ITER Organization.

The first test results are expected in late November; several dozen test series will follow. The results will make it possible to adjust the manufacturing technology for these challenging plasma-facing components.

The first test results are expected in late November; several dozen test series will follow. The results will make it possible to adjust the manufacturing technology for these challenging plasma-facing components.

The works are being carried out in the presence of Russian and Japanese Domestic Agency specialists, as well as experts from the ITER Organization.