What’s New

29 June 2015

ITER news digest for the period of 22 June 2015 to 29 June 2015.

X marks the spot

JET's next tritium experiments materialize

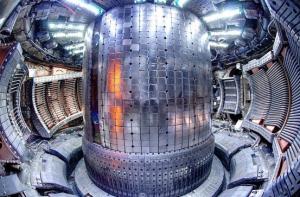

June issue of F4E News

Hot forming the vacuum vessel