Procurement for residual gas analyzers signed with US-DA

30 Sep 2011

-

Krista Dulon

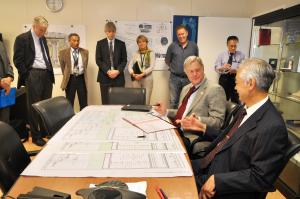

US ITER Project Director, Ned Sauthoff, and Director-General Motojima signing the Residual Gas Analyzer Procurement Arrangement. The RGA diagnostic will have responsibility for "deciphering" the composition of neutral gases in ITER.

On the inside of the ITER vacuum vessel where extreme temperatures reign, the attraction between electrons and their nuclei is overcome and gas becomes a plasma—the hot, electrically charged environment that is the breeding ground for fusion reactions.

The reverse phenomenon is produced at the edge of the plasma: the ions lose their electrical charge as they come into contact with the material surfaces of the vessel and a neutral gas is formed between the vessel walls and the edge of the plasma.

Sampling this edge gas to decipher its exact composition—both at the machine's mid-level and at the divertor level where exhaust is pumped out—will furnish ITER operators with important information about the plasma and plasma-wall interactions.

Responsibility for sampling and analyzing the composition of neutral gases during operation will fall upon two residual gas analyzers (RGAs) in ITER. The Procurement Arrangement for these diagnostics was signed last Friday, September 23 by Director-General Osamu Motojima and US ITER Project Manager, Ned Sauthoff.

The RGA diagnostic systems will be installed in shielded environments away from the intense magnetic field and the neutron emission of the ITER machine. Neutral gas sampled at the level of the equatorial port plug or divertor pumping duct will be transported through long pipes (up to 14 metres) to be analyzed under controlled conditions. "By continuously identifying the neutral gas composition in the main chamber and in the divertor exhaust," explains Philip Andrew, ITER's Technical Responsible Officer for the RGA Procurement Arrangement, "operators will have information on the efficiency of the divertor in removing helium from the plasma. Helium is the natural byproduct of the fusion reactions, but if allowed to accumulate in the plasma, it displaces the deuterium and tritium fuel and reduces the fusion reaction rate."

Procurement Arrangement number 60 for the ITER Organization.

The RGA diagnostic for ITER is designed as a dual-sensor system. A mass spectrometer will determine the mass-to-charge ratio, or "signature," of each constituent by locally ionizing the neutral gases. This signature is unique and identifiable except in the case of helium and deuterium, which have the same mass-to-charge ratio. A second sensor, the optical gas analyzer (OGA), will create a small discharge to excite the gas molecules into emitting light. The OGA will be able to distinguish between helium and deuterium by measuring the spectrum of light from this discharge, each gas species will emit at unique characteristic wavelengths.

"Much like an emissions test for a car," comments Chris Klepper from the Oak Ridge National Laboratory, who is directing the RGA project for the US-DA, "the RGA analyzes the constituents of the exhaust from the ITER reaction chamber and can provide information on the cleanliness and efficiency of the burn cycle. The challenge on the design and manufacture of a diagnostic system like this on a nuclear fuel burning plant is that it has to sample from a significant distance, while still maintaining useful response time. The sensitive instruments have to be shielded from strong magnetic and electromagnetic interference, and the sampling tube has to handle vibrations and maintain its integrity even in the very unlikely event of an earthquake. We look forward to meeting these challenges and providing this important diagnostic system to ITER."

"Much like an emissions test for a car," comments Chris Klepper from the Oak Ridge National Laboratory, who is directing the RGA project for the US-DA, "the RGA analyzes the constituents of the exhaust from the ITER reaction chamber and can provide information on the cleanliness and efficiency of the burn cycle. The challenge on the design and manufacture of a diagnostic system like this on a nuclear fuel burning plant is that it has to sample from a significant distance, while still maintaining useful response time. The sensitive instruments have to be shielded from strong magnetic and electromagnetic interference, and the sampling tube has to handle vibrations and maintain its integrity even in the very unlikely event of an earthquake. We look forward to meeting these challenges and providing this important diagnostic system to ITER."