A constant health check

ITER, as the first reactor-scale fusion device, will help the world understand more about the necessary tradeoff between maximal performance and equipment lifetime. A new suite of software, the tokamak systems monitor, will assist engineers in striking the right balance—and more.

From a huge volume of data to an intuitive presentation

Exploring the operating profile of ITER is a complex task—and even though the machine was designed for robustness, all operations must be performed with extreme care. If sensor data processed by the tokamak systems monitor indicates that one or more systems reacts too far from the expected range, operators will analyze possible causes and make adjustments to home in on exactly what is going on. If on the other hand, all systems behave well, they will increase loads to further optimize the performance against design parameters.

The primary source of information used by the TSM diagnostic is a collection of operational instrumentation sensors that are generally provided with the equipment they measure (for example, magnet coils) and that are separate from the specialized diagnostics used to monitor the main plant systems. Complementary data will be taken from plant systems such as water cooling and coil power supplies, as well as from the plasma control system and the diagnostics that measure events from the plasma to the first wall.

Even with all this input, the tokamak systems monitor will still have gaps to fill, simply because putting a sensor on every component and in every critical location would be impossible. Using a process called "reconstruction," the tokamak systems monitor will take information from local sensors and apply carefully developed and tested analysis and simulation models to figure out the behaviour of the entire machine.

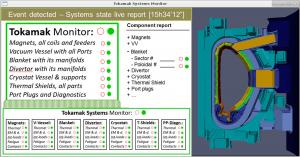

The software suite will routinely serve up a health status, and actual machine margins, to operators. At a simple level, one can think of the presentation as lights representing each system, remaining green when all is well, and flipping to amber or red if some action has to be taken. From this simple dashboard, experienced operators will be able drill down much deeper to find out what is happening across the whole plant.

Considering the number of interactions between the different systems, it is easy to appreciate the unique value of the tokamak systems monitor.

Interleaved reconstruction algorithms and simulation models

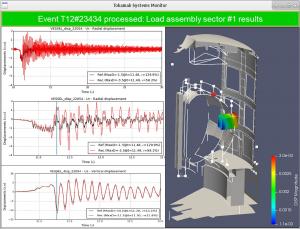

The tokamak systems monitor starts by applying sophisticated reconstruction algorithms that take sensor data and reconstruct global behaviour of the tokamak, taking into account the timing of each event. The algorithms are said to be "interleaved" in that any given algorithm may cover several tokamak systems, and any given tokamak system may be served by multiple algorithms.

These freshly reconstructed global parameters are then used as input for simulation models—usually based on finite element analysis—to calculate specific engineering data for all points of interest, and compare those with a range of limits to report to the operator. The tokamak systems monitor also archives the output for future use.

Through this process, the software is able to deliver specific engineering data for all parts of the machine—including locations where sensors cannot be installed, or where they were installed, but are no longer functioning.

"The second thing that's unique," adds Sergey Sadakov, Tokamak Systems Monitor Engineer, "is that unlike all industrial applications of similar diagnostic systems, we are taking an unusually large step from current machines to ITER. Some of the modern tokamaks do have some instrumentation and use some reconstruction algorithms. But if you compare the volume of instrumentation and the variety of parameters they have to reconstruct with what we do at ITER, the difference is one or two orders of magnitude. We are taking one giant step up to several tens of thousands of channels of data coming in, and several hundred reconstruction algorithms and simulation models running simultaneously. This is the future of fusion, the dawning of an industrial approach."

Refining engineering models well before the machine becomes operational

"Our development strategy is to have six releases of the software suite, each with consequently wider functionality," says Iglesias. "In a year we will demonstrate the first working version—of course with limited functionality, but with the basic ingredients. And then the development will be incremental. The full system will be ready at the end of 2024, to be integrated before First Plasma. The upgrades will keep coming even after the machine begins operation. Once the ITER Tokamak is operating we will start with the validation phase, and then I'm sure we'll have a lot of ideas on how it can be improved."

But even now, years before the reactor becomes operational, the tokamak systems monitor simulation tools are playing an important role. By comparing the output from the simulators to the engineering models used in design, scientists and engineers are able to make changes to engineering models far in advance.

"Thanks to the development of the simulation models, we are already able to check the designs and make sure any cross-couplings are handled well," says Alexander Alekseev, Senior Advisor on tokamak engineering to the ITER Director-General. "So well before First Plasma, this system is already adding value to the development of the ITER machine."