What’s New

2 November 2015

ITER news digest for the period of 26 October 2015 to 2 November 2015.

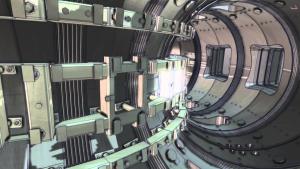

A precious contribution to MIT's proposed tokamak

Plasma heating puzzle comes together