Material erosion under fusion-relevant conditions is of critical importance for all materials applied to ITER. A recent campaign at the German-based tokamak

TEXTOR, jointly conducted by the Research Centre in Jülich and the Japanese University of Tohoku upon the initiative of the International Energy Agency (IEA), studied the erosion and melt behaviour of tungsten on a longer timescale.

Founded in response to the 1973/74 oil crisis the International Energy Agency (IEA), with its headquarters in Paris, is an autonomous organization which works to ensure reliable, affordable and clean energy for its 28 member countries and beyond. Today, one of the main focus areas is energy security, i.e., promoting diversity, efficiency and flexibility within all energy sectors and most of all ensuring the stable and economical supply of energy for the future.

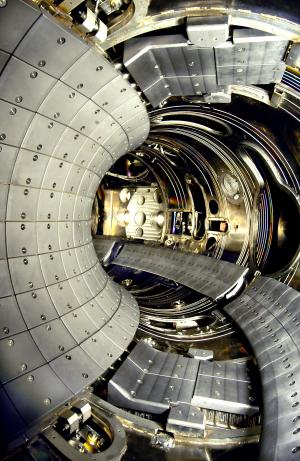

One of IEA's Technology Initiatives—also known as Implementing Agreements—is the Program of Research and Development on Plasma-Wall Interaction in TEXTOR which has existed since 1978 with its member countries USA, Japan, Canada and the European Union. TEXTOR—a medium sized tokamak operated by Forschungszentrum Jülich (FZJ) in Germany—was constructed in 1982 to develop novel technologies for the extraction of energy from the burn chamber of nuclear fusion reactors. Due to its configuration TEXTOR is predestined to run so-called "high risk" experiments that could not be conducted easily in other fusion machines.

While in the past experiments at TEXTOR under the IEA Technology Initiative focused on thin-film coating technologies for large burn chambers (e.g., boronization and carbonization) as well as helium pumping and the optimization of graphite tiles, current test campaigns focus on the testing of tungsten structures in the boundary plasma of the TEXTOR machine.

As a best-choice material for the divertor, tungsten is of crucial importance for the success of ITER and that of later power plants (also see Newsline

#206 and

#207). To determine the material's limits or operational regime, fusion scientists from Japanese universities and research institutes met in Jülich from 23-28 January to perform joint experiments with their colleagues from Forschungszentrum Jülich, using TEXTOR as the test bed and the IEA Implementing Agreement as the organizational frame.