Vacuum vessel

Windows with tailored appendages

23 Oct 2017

-

Sabina Griffith

Each of the vacuum vessel's 44 openings will have custom-made "extensions" to create the junction to the cryostat. The first link in the two-part chain—the port stub extension—will be welded to the vacuum vessel sectors before they are shipped from their manufacturing locations; (the second, port extensions, will be added during assembly on site). The first port stub extension is on its way now to Korea.

Although small compared to the vacuum vessel itself, these custom-made components are impressive when you consider that they will be welded to all of the upper and lower port stubs of the ITER vacuum vessel. The stub extension for port #12 weighs more than 17 tonnes and measure 4 metres x 2.5 metres, for 3.4 metres in length.

Another ITER component has taken to the sea, heading to the shores of South Korea. Its destination? Hyundai Heavy Industries—principal contractor to the Korean Domestic Agency for the manufacture of Korea's portion of the ITER vacuum vessel. Manufacturing is at an advanced stage there for vacuum vessel sector #6—the first sector scheduled to reach ITER. The port stub extension shipped last week will be welded to its upper port stub.

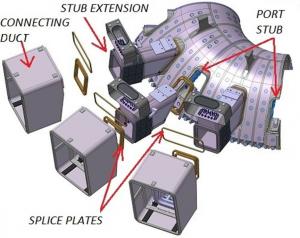

Port structures will create the junction between the vacuum vessel and the cryostat. The first of these—stub extensions—are shown at upper port level in the above diagram. These stub extensions will be prolonged by port extensions (not shown) during in-pit assembly at ITER.

The port stub extensions, which are an integral part of the ITER vacuum vessel, will be welded to all the openings (or "ports") at lower and upper levels. The upper stub extensions are characterized by a trapezoidal/rectangular cross-section. Although they appear small compared to the vacuum vessel itself, these custom-made components weigh upwards of 17 tonnes and measure 4 metres x 2.5 metres, for 3.4 metres in length.

As part of the vacuum vessel, the stub extensions are subject to French regulations on pressure equipment (ESPN). "Achieving water pressure tightness was one of the main design criteria for this challenging component," says Yuri Utin, from ITER's Vessel Division. Last January, the stub extension for upper port #12 was able to demonstrate leak tightness in pressure tests up to 3.78 MPa for the 30 minutes required by regulations. The helium leak tests that followed were also successful, as witnessed by representatives of the ITER Vacuum group.

Other challenges included manufacturing to tolerances of < 6 mm (for a shell thickness of 60 mm and a double-shell construction thickness of up to 200 mm); achieving defect-free welding in the attachment of the numerous pipe stubs on the main bulkhead; and carrying out full volumetric and visual examination of these welds and other welded joints in a context of difficult access, according to Yuri.

At MAN Diesel & Turbo, in Deggendorf, Germany, the port stub extension for upper port #12 successfully passed pressure and helium leak tests. It left the factory mid-October for shipment to Korea.

The manufacturing of the first upper port stub extension is part of the more global procurement of the upper ports under the responsibility of the Russian Domestic Agency. Its main supplier for all upper ports, the Efremov Institute in Saint Petersburg, is responsible for contracting out to procure the specific austenitic stainless steel required, performing structural and other analyses, checking and approving the manufacturing design, and controlling the manufacturing progress. The German company MAN Diesel & Turbo, based in Deggendorf, Lower Bavaria, was chosen to be the main sub-supplier for the manufacturing design and fabrication.

Once the port stub for upper port #12 reaches Korea, it will have to pass site acceptance tests in the presence of representatives of the Korean and Russian Domestic Agencies and representatives of the ITER Organization.