A tokamak must breathe

When plasmas ten times hotter than the core of the Sun begin pulsating inside the ITER vacuum vessel, the combined mass of the Tokamak and cryostat (25,000 tonnes) will need a bit of breathing space. Not much—but enough to accommodate the wobbling, expansions and occasional displacements caused by the tremendous forces at work in the machine.

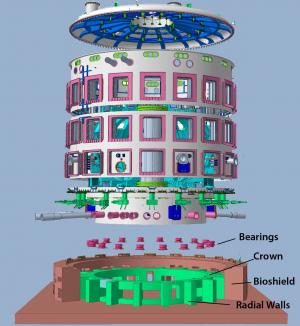

In order to protect the installation and guarantee its safety, the Tokamak support system will need to be both extremely robust, with a strong connection to the Tokamak Complex basemat, and yet allow for a slight freedom of movement for the cryostat.

However while the mechanical principles at work in the ITER Tokamak support system are the same, the materials implemented will need to be very different.

It took about six months of research and the testing of dozens of alloys, ceramics and compounds before settling on a copper-aluminium alloy that—combined with a micro lubricant (molybdenum sulphur)—would do the job to perfection. The combination already works for other ITER systems, in some components of the Wendelstein stellarator, and in deep-space applications.