Teamwork in action: ITER diagnostics and electromagnetic design

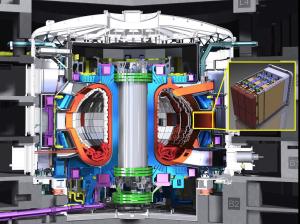

ITER diagnostic systems will be vital in controlling the plasma as well as evaluating and optimizing machine performance. Required to "see" the plasma from many different angles, diagnostics will be installed in different locations around the vacuum vessel, integrated in port structures called "port plugs."

Port plugs are massive components—up to 50 metric tons each—that seal the vacuum vessel port openings during operation and that will provide shielded housing, as well as a front-row seat, for instruments. At least 22 of ITER's 33 port plugs will be customized to house diagnostics.

The major driver for the structural design of the generic equatorial and upper port plugs has been the need for the port plugs to withstand disruption forces and plasma vertical displacement events (a sudden vertical displacement of the plasma that can lead to extremely heavy loads). Although of extremely short duration—on the order of a few tens of milliseconds—they would induce large electromagnetic loads on the structural components of the port plugs.

To study and predict these electromagnetic loads, and inertial effects, a joint ITER-PPPL team has come together to develop efficient and cost-effective electromagnetic (EM) analysis models able to handle interfacing actions. The team has also developed a critical electromagnetic data mapping procedure to integrate electromagnetic analysis with the structural analysis that defined load specifications for the generic plug and first-wall designs. This will ensure the structural integrity, and sound dynamic behaviour, of the diagnostic infrastructure for integration into the port.

A multi-physics engineering analysis protocol—with CAD design models integrated into state-of-the-art analysis tools—has been developed and implemented as a baseline methodology established for the port plug structure and first wall design. As a result, the ITER design can be cost effective, consistent and soundly justified through analysis.