Successful demonstration of diagnostics instrumentation

CODAC (Control, Data Access and Communication) is the central, conventional control system responsible for operating the ITER device. It provides the interface "language" for 220 ITER plant instrumentation and control (I&C) systems containing actuators, sensors and all instrumentation and control functions required to measure and control the plasma parameters.

Because plant I&C systems are being procured together with the plant systems from the ITER Members, whereas CODAC is implemented by the ITER Central Team, the interface between the central system and the plant system I&Cs must be well defined and strictly adhered to. A uniform, standardized approach to design of plant system controls is also important to reduce overall project manufacturing and maintenance costs.

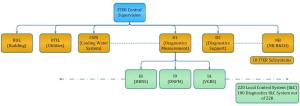

In order to facilitate integration, CODAC has organized plant system I&Cs into groups that represent the functional needs of tokamak operation (as illustrated in the image below, levels 1 and 2). Diagnostics represents about 50 percent of all ITER plant I&Cs.

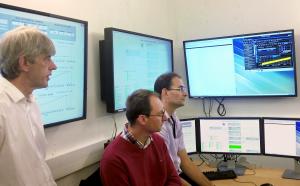

In the latest practical demonstration, a prototype of a neutron diagnostics plant I&C system was demonstrated to a large group of diagnosticians in the CODAC control room—a specially equipped facility located in the basement of ITER Headquarters.

The divertor neutron flux monitor, procured through the Russian Domestic Agency, is a diagnostic that measures the fusion power of the ITER Tokamak. In a close association between the ITER CODAC team and Russian colleagues, the idea was born to convert a diagnostic plant I&C example (created with the objective of simplification, cost reduction, standardization and full integration with ITER control system) into a basic plant I&C of a real diagnostic for evaluation by the Russian Domestic Agency.

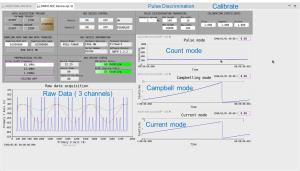

The design followed the standard system engineering methodology developed for diagnostics and implemented in compliance with the Plant Control Design Handbook (see insert below), utilizing CODAC Core System and CODAC-provided tools and data repositories. The implementation followed extensive testing documented in detailed reports. Before shipping the plant I&C to Russia, a demonstration was made in manual and automated operation to large group of diagnosticians in the CODAC Control Room.

The demonstration proved that complex, and high performance diagnostics can be built in compliance with the ITER Plant Control Design Handbook, while meeting the stringent requirements of the diagnostics.

The fusion power measurement is based on fission chambers which produce short electrical pulses where the pulse rate is proportional to the fusion power. To cover the wide dynamic range of more the 6 orders of magnitude and a fast measurement update every millisecond, a complex analysis of millions of data samples are required. The demonstration covered not only the aspects of high performance data processing but also the needs for the execution of elaborated procedures such as various types of calibrations, built-in health management, raw data archiving, and finally the fully automated operation that will be supervised by the central CODAC system. This is the first time diagnostic plant I&C is fully based on the CODAC technology, making use of the latest CODAC features.