Starting with the heat rejection system

Commissioning of the heat rejection system is well underway, clearing the path for all "client" systems.

"Commissioning started in August 2021 when we received the turnover certificate," says Thomas Pralus, the Cooling Water Engineer in charge of commissioning the heat rejection system. "This formalized the transfer of ownership from the construction teams to the commissioning team within the Operations Division. Of course, we started what we call 'cold commissioning' a bit earlier. We did the loop checks, testing around 1,000 input/output signals—including temperature sensors, pressure and flow transmitters and vibration sensors that monitor the process during commissioning and, ultimately, during operation."

The team reached a major milestone in September. "We started the first motors and demonstrated they worked in isolation. After performing this motor 'solo run test' we started 'warm commissioning,' coupling the motors with the pumps."

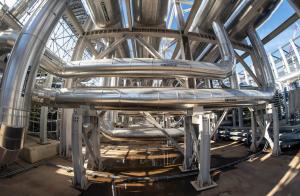

The first task was to mechanically align the motors to the pumps. The heat rejection system has 13 vertical pumps submerged in the 7-metre-deep basins and powered by electrical motors. From the cold basin, water is pumped to the heat exchangers, then to the cooling tower, and back to the basin to complete a closed loop. The team started running a single pump in November 2021. A week later they ran three pumps in parallel, reaching a flow rate of 4200 kilograms per second.

"We are now in what we call 'flushing' operation," says Pralus. "This is the first time we circulate water from our pipeline into our basin. Before passing through the plate heat exchangers, we want to be sure all the pipes are clean. To do this we bypass the heat exchangers and run the pumps to reach nominal velocity in the pipes to remove all the dirt. When we complete flushing in early 2022, we'll be able to integrate the plate heat exchangers, which will remove the heat load."

One big remaining task for the team is testing the 10 cooling towers. A lot of cold commissioning has already been done there, including all the instrumentation of the cooling tower fans; the next step is to start the fans.

"There will be a big increase in commissioning activities at that time, and all of it has to be done in parallel, by the same team," says Thierry Menguy, Commissioning & Operations Management Officer. "We only have a few commissioning engineers, so we have to be very well organized to get it all done. The very good news is that the operation team, consisting of principal shift operators and shift operators, is already in place and is currently supporting a lot the commissioning activities."

As commissioning continues for the heat rejection system, preparations are underway for commissioning of other secondary cooling water systems needed for First Plasma. "All commissioning activities require documented test procedures," says Menguy. "We are currently preparing this documentation to be ready to begin."

If all goes according to plan, by the end of 2022, four secondary cooling water systems will have been fully tested in addition to the heat rejection system.

Commissioning the control software

Laura de Frutos Bolzoni, Control Systems Integration Engineer, is responsible for integrating the cooling water systems with the central control system CODAC. "Commissioning the cooling water systems is a lot of work. These systems are very large-scale, covering the whole ITER platform. The heat rejection system is only one part of that."

To test the control system and its integration with CODAC, the commissioning team checks sensor by sensor, wire by wire, verifying that everything is well connected Then it checks all the inputs and outputs, and all the actuators. The team follows all these steps for each device of the cooling water system, before moving on to functional tests.

"During the tests we interact with many different stakeholders, requiring us to understand different perspectives. Control room operators see things differently than field operators, and the process people have a completely different perspective. We take our time, we listen, and we make sure that each part of the complex cooling water control system is working as it should."