Smallest crane gets a lift

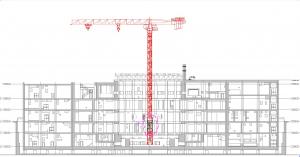

Towering 50 metres above ground, "C1" is the shortest of the five tower cranes operating inside the Tokamak Complex. Standing at the very centre of the bioshield—almost exactly materializing the axis of the ITER machine—it is the one we point to when we have visitors on the worksite.

"Cranes are like Lego," explains Laurent Moustraire, the "master of cranes" for the European VFR consortium responsible for building the Tokamak Complex and eight other buildings on site. "Within limits, they can be modified almost at will." In the context of the new phasing, C1's mast will be extended approximately 10 metres, allowing the boom to operate well above the upper level walls.

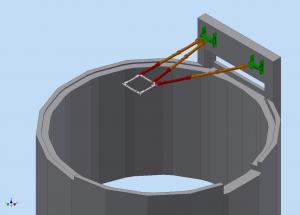

A similar procedure was followed for the extension of crane C1. As the wind effect will be greatly increased in the new, taller configuration, it was determined that the mast needed to be reinforced at its base and that extra anchorage had to be created. To this end a set of three steel tubes (Ø 40 cm) will be bolted to one of the heavy concrete walls that stands above the bioshield as shown in the diagram at left.