It's happening on site

12 Oct 2015

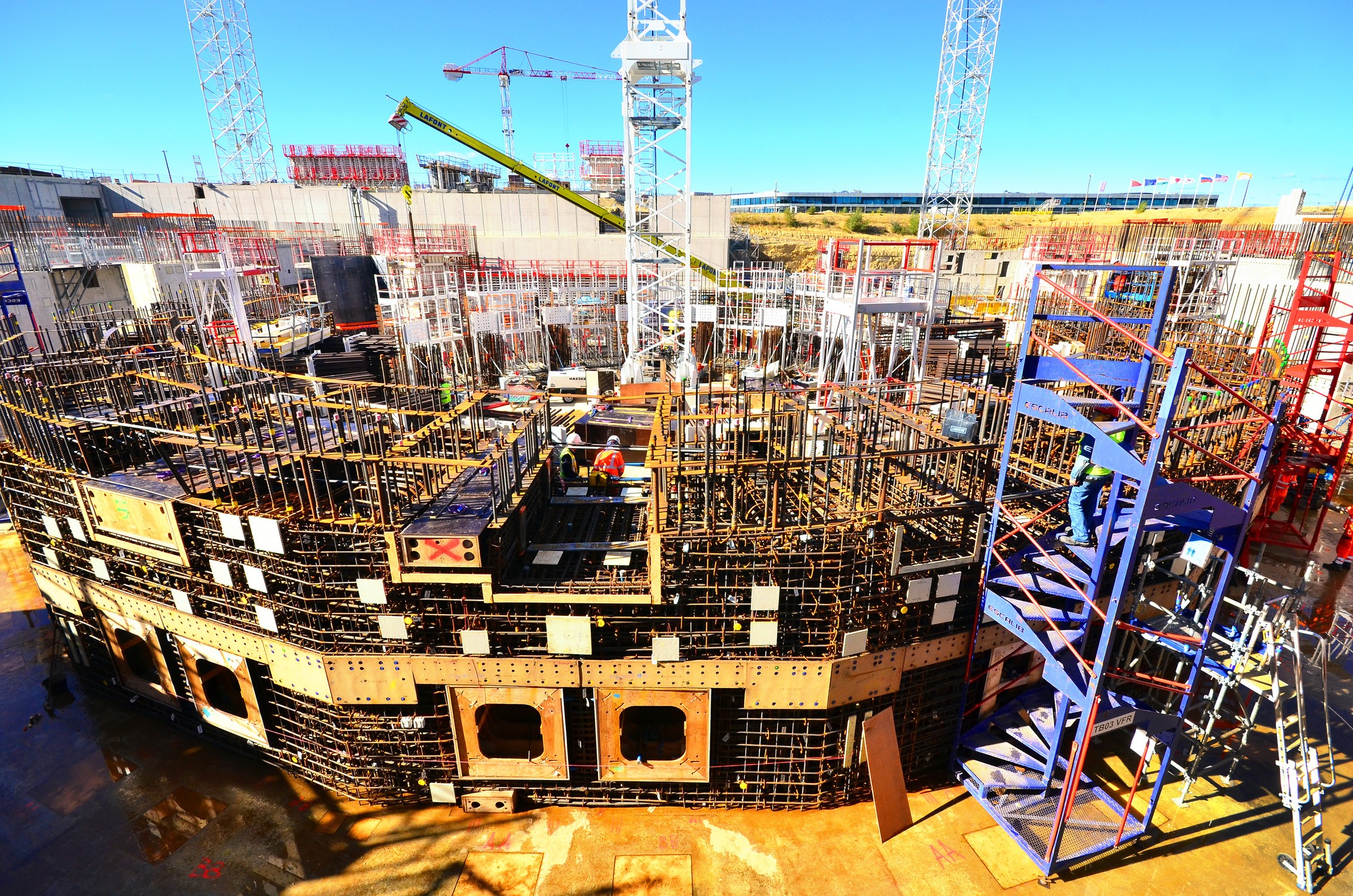

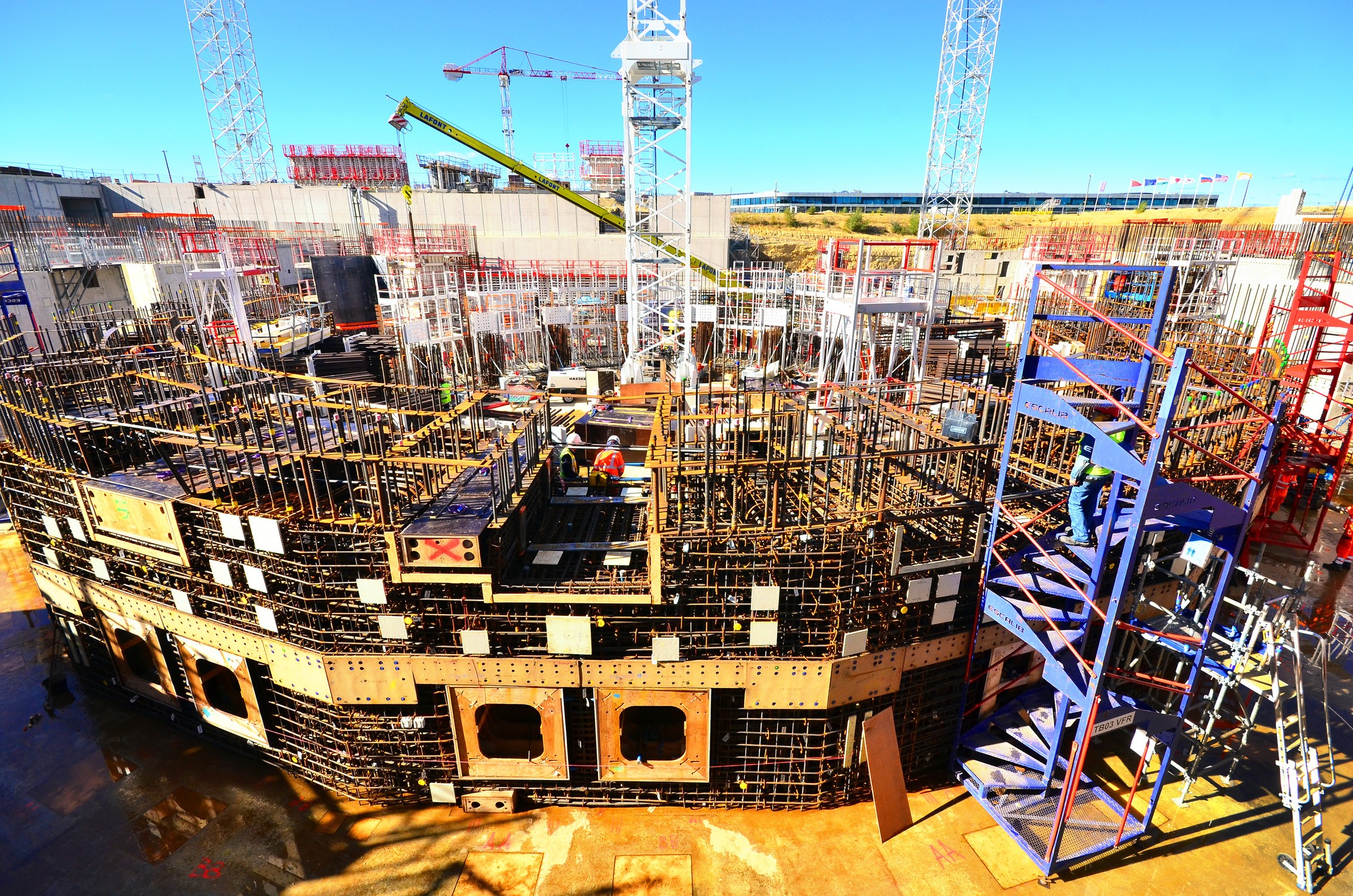

Work to install the rebar of the 3.2-metre-thick bioshield was carried out from April to September 2015. Concrete pouring will begin this month for the first 200° segment. As the density of steel reinforcement prevents the use of concrete vibrators (part of the normal concrete pouring process), a specially formulated self-compacting concrete will be used. Pouring operations on the bioshield will continue through January 2016.

Between the 18 massive columns that provide structural support to the different levels of the Tokamak Complex, walls will be made of a special, high-density concrete (3.9 tonnes per cubic metre as compared to 2.5 tonnes for regular concrete). Producing the concrete on-site will require 6,000 tonnes of magnetite gravel that is being shipped from Kiruna, in Swedish Lapland. Inspecting one of the completed walls (out of 18) are Paul Lugardon (BIPS buildings project team) and Benjamin Sar (VFR consortium).

Preparatory works have begun for the buildings that will house the giant magnets power conversion units. Like for all other buildings the process kicks off with "soil investigation," where long drill bits are pushed as much as 15 metres below the surface in order to identify possible discontinuities or cavities created by water erosion (karsts). Holes are bored approximately every five metres.

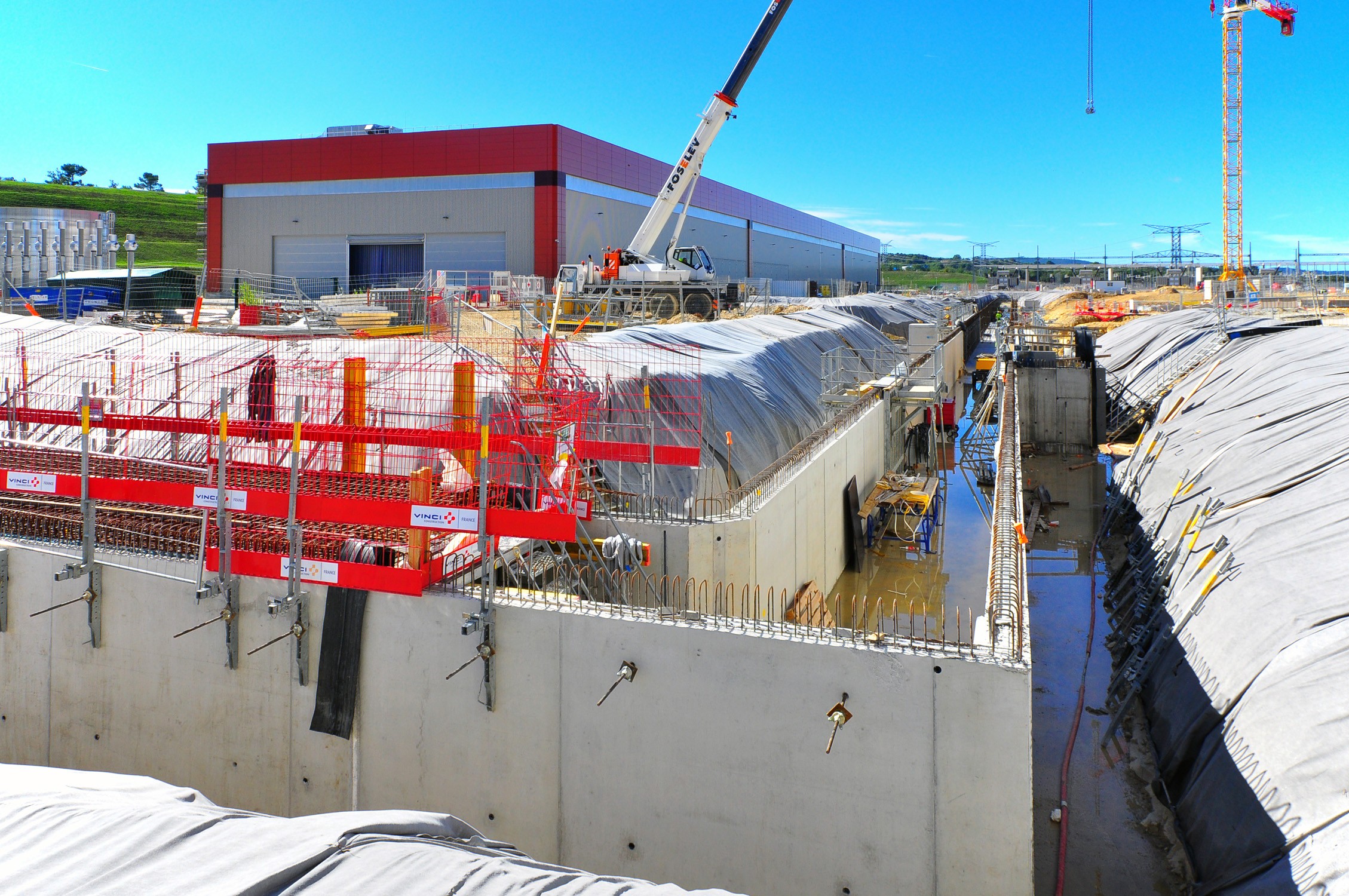

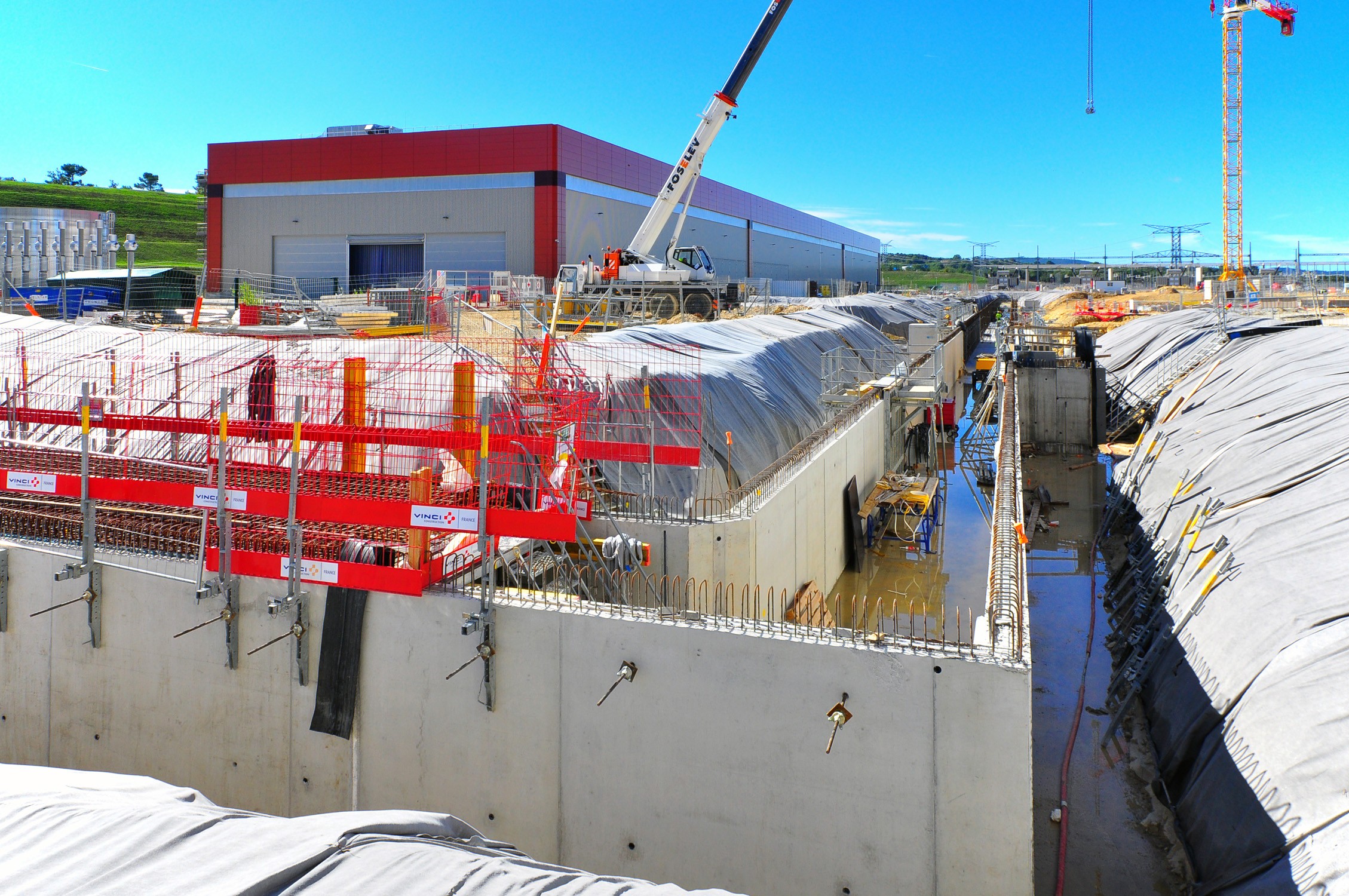

Excavation has started for the ITER Cryoplant Building near the Assembly Hall. The 121-metre-long, 47-metre-wide and 19-metre-high Cryoplant Building will host one of the world's largest clusters of cryogenic equipment.

Plastic caps of many colours (according to the diameters of the steel bars) protect the couplers that will ensure the vertical continuity of the bioshield's steel reinforcement.

A giant, 22-legged arachnid seems to have taken residence on the ITER site ... Following the roof lifting operation on 11 September, the temporary structures that held the hydraulic jacks have been removed and workers have nearly finished tightening 3,000 connexion bolts. In the bottom left hand corner a piece of cladding is visible, part cladding trials currently underway.

The Site Services Building will accommodate and distribute a large number of industrial support services that are indispensable for operating ITER. Among these, a chiller plant will feed cooling water to buildings through a four-kilometre network of piping. Concrete pouring for the 80-metre-long facility has started.

Work on the platform technical galleries is not quite completed (here, "area 5" along the Poloidal Field Coils facility). In all, four kilometres of underground galleries will service the ITER scientific installation.

Transformers are made of hundreds of parts that can only be assembled once the main body is in its final position. After a few months of intensive work, the four SSEN 400kV transformers, part of the US procurement to ITER, are now fully assembled and filled with 60,000 litres of insulating oil each.

In ITER's largest on-site manufacturing facility, the Poloidal Field Coils Winding Facility, work has begun to prepare for the start of industrial activities. Since July, two clean areas for "white rooms" have been framed out and the first crates of equipment have been delivered and stored in preparation for the installation of full winding tooling in October.