Filling the gap

Inside the Tokamak assembly pit, two small machines are entrusted with a formidable task: faultlessly and seamlessly welding the first two sections of the cryostat. Following the manual welding of feeder stubs and "manways," and the initial manual passes on both sides of the weld joint between the base and the lower cylinder, the time has now come to join both components. The delicate operation, which began on 26 October, will take approximately five months to fully complete.

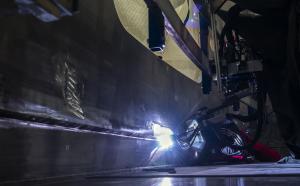

Equipped with a flat head that is half-inserted into the gap, the machine uses a welding technique called "gas tungsten welding". A tungsten electrode creates an electrical arc that melts the filler material, which is deposited, pass after pass, inside the gap. All in all, the welding process will require close to one tonne of filler material.

As soon as two six-metre-long sections are completed, the quality of the weld is tested using non-destructive ultrasonic test examination. As for helium tests, they will be performed when the whole 90-metre circumference is finalized.

With the planned addition of a third welding machine, the operation should take approximately 65 workdays, which amounts to approximatively three-and-a-half months. An additional month-and-a-half will be necessary for tests and documentation after the welding is complete.