Exciting developments in China

Last week, several members of the Magnet Division joined me to visit industries and institutes in China. This was my first trip to China and I was eager to see industrial capabilities first hand and to meet the design teams working on important systems for the Tokamak. David Sands, Head of ITER's Quality Assurance Division, joined us for part of the trip to discuss procurement quality procedures. This is particularly important for magnet components.

China is heavily involved in many magnet components including: toroidal field, poloidal field, and correction coil conductors and magnet feeders. Our first company visit was with WST—a superconducting strand supplier in Xi'an. This company has constructed many new facilities but has limited production experience. Our discussions centered on quality assurance and control, facilities, training, and documentation. The conductor database that has been developed by the ITER Organization was fully discussed, as it is a critical tool to manage the information on the thousands of billets and conductor samples required for the project. We were happy that this company had used similar databases before.

Just a few kilometres from Xi'an is the Mausoleum of Emperor Qin Shihuang, and its 8,000 terra-cotta figures dating from 210 B.C. and discovered in 1974. This site gives a historical perspective of the technical capabilities of the region. Not only was this vast construction project completed in 38 years—an impressive construction management achievement—but also large-scale bronze casting technologies were developed, as well as a chrome-plating technique for bronze weapons that protected them from corrosion even after being buried for more than 2,000 years. Unfortunately, much of the technology was lost since the labour force was buried alive after construction.

Our second company visit was to Baosteel in Shanghai. This company has very modern facilities capable of producing high-quality conductor jacket such as that required for the central solenoid conductor: a square jacket with an internal circular hole. This company has plenty of capacity and may be an attractive option from a cost standpoint. The impact of the global financial crisis was clear in this modern facility where many of the furnaces lay idle. To minimize layoffs during this downturn, they have chosen to reduce pay and continue to employ as many as possible.

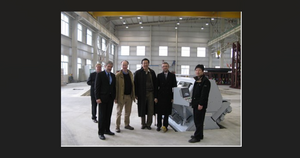

Our third visit was to ASIPP, where we discussed magnet feeder and correction coil design activities and progress related to the procurement of toroidal and poloidal coil conductor. Significant design progress has been made and our priorities are beginning to shift from design to Procurement Arrangement preparation. Activities related to toroidal and poloidal conductor procurements are particularly impressive and the Chinese are moving ahead aggressively. The toroidal field and poloidal field conductor jacketing building is nearly complete. This includes the 900-metre jacketing line. Both winding and compaction machines have already been procured and are sitting on the floor. Soon facilities like this will be under construction all around the world. This is an early sample of exciting times ahead.